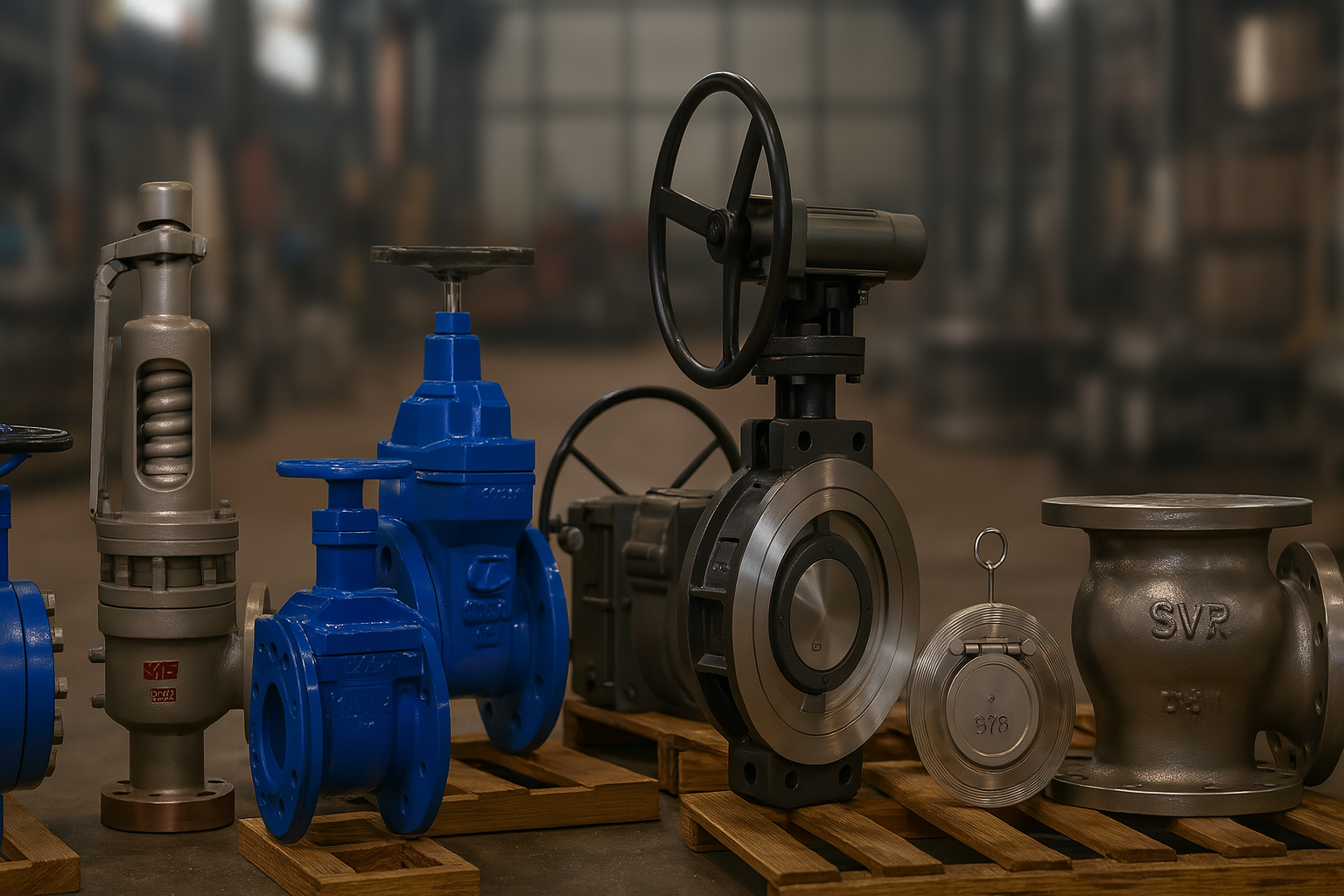

Water Treatment Industry

Middle East Valve supplies specialized valves designed to ensure reliable performance across all stages of water treatment — from raw water intake and filtration to chemical dosing and distribution. Our solutions help maintain flow control accuracy, reduce water hammer, and ensure system integrity in potable and wastewater treatment plants.

Valve Solutions Offered:

- Butterfly Valves – Resilient seated for isolation and throttling

- Globe Valves – For precise flow regulation in dosing and control applications

- Check Valves – Non-slam and swing types to prevent backflow

- Knife Gate Valves – Ideal for sludge and slurry handling

- Air Valves – Single and double orifice for pipeline air management

- Foot Valves – Prevent reverse flow at suction lines

- Pressure Reducing Valves – Maintain consistent outlet pressure in distribution

Key Benefits:

- Designed for low-pressure, high-cycle operations

- Available in ductile iron, bronze, stainless steel, and epoxy-coated carbon steel

- Long service life in corrosive or abrasive environments

- Easy maintenance with top-entry or bolted bonnet designs

- Optional automation for SCADA-integrated systems

Application Areas:

- Municipal and industrial water treatment plants

- Effluent and sewage treatment plants (STPs/ETPs)

- Raw water intake stations and pumping lines

- Sludge and sedimentation control units

- Chemical dosing and filtration systems

- Distribution and reservoir control