- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

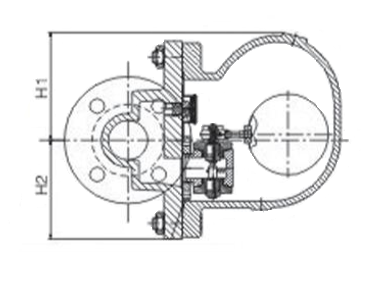

Ball Float Steam Trap Supplier in Saudi Arabia: Continuous and Efficient Condensate Removal

Middleeast valve is the foremost Ball Float Steam Trap Supplier in Saudi Arabia. It is a type of automatic steam trap used in steam systems to remove condensate (the liquid formed when steam cools) while maintaining the steam pressure within the system. It uses a ball float mechanism to control the discharge of condensate.

Key Components of Ball Float Steam Trap:

- Float Mechanism: Stainless steel ball floating up and down with the level of the condensate.

- Valve and Seat: It regulates the condensate discharge.

- Air- Vent: Non-condensable gases are discharged through an air vent.

- Body: Typically made of carbon steel, stainless steel, or cast iron.

Working Mechanism:

- Condensate accumulates within the chamber as steam enters the trap.

- The valve is removed from its seat to discharge the condensate when the ball float rises in proportion to the condensate level.

- The valve closes when the float falls after the condensate has been drained.

- No loss of steam during continuous operation of the trap.

Advantages of Using Ball Float Steam Trap:

- Continuous discharge of condensate.

- Live steam is not wasted.

- High resistance to corrosion and pressure.

- Low service life and maintenance.

- Efficient air ventilation during startup.

Functions of Ball Float Steam Trap:

- Condensate drainage

- Avoiding wastage of steam

- Gassing off and air removal

Industries:

- Gas and Oil

- Petrochemical

- Power Plants

- Textile

Description:

Available materials: Cast iron, WCB, WCC, WC6, LCC, LCB, Titanium, SS304, SS316, CF8, CF8M , F55, F51, F53, Monel, Ductile Iron.

Available Size: ½” to 48”

Class: 150 to 2500

Ends: Flanged, Threaded, Buttweld, Socket weld

Operations: Lever Operated, Electric Actuated and Pneumatic Actuated, Gear