- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

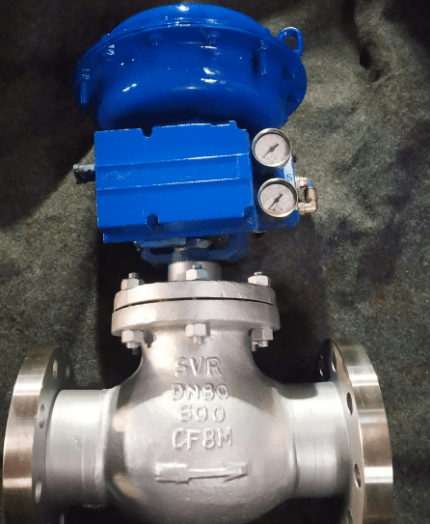

Pneumatic Sleeve Type Control Valve Supplier in Qatar: Easy Flow Regulation

Middleeast Valve is the foremost Pneumatic Sleeve Type Control Valve Supplier in Qatar. It is control valve with an internal flexible sleeve utilized to regulate the flow by opening or closing, based on the air pressure put on the actuator. It offers close shut-off as well as smooth throttling, especially under challenging flow conditions.

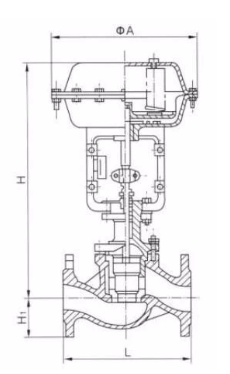

Parts:

- Valve Body – typically constructed of cast iron, stainless steel, or ductile iron

- Rubber or Elastomer Sleeve – the middle component that flexes to control flow

- Pneumatic Actuator – uses air pressure to push the sleeve

- End Connections – threaded or flanged to insert into pipes

- Positioner (optional) – used for better control of flow rate

Working Mechanism:

The valve operate by supplying compressed air to actuator, which expand or compress internal elastomer sleeve. Expansion or contraction of sleeve change diameter of flow passage, allowing controlled flow rate modulation. Upon release of air pressure, the sleeve returns to its initial shape, typically through a spring mechanism.

Advantages:

- High abrasion and corrosion resistance

- Applicable to slurry, wastewater, and viscous fluids

- Bubble-tight shut-off

- Low maintenance with minimal moving parts

- Smooth, precise flow control

Industries We Serve:

- Mining and Mineral Processing

- Chemical and Petrochemical

- Pulp and Paper

- Water and Wastewater Treatment

- Cement and Power Plants