- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

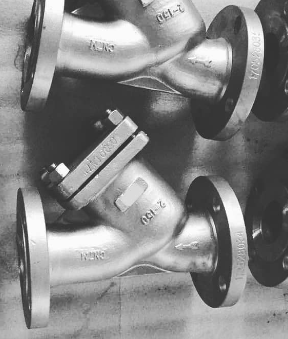

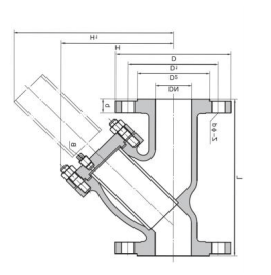

Y Strainer Manufacturers in Saudi Arabia: Compact and Effective Filtration Solutions

Middleeast valve is well known for Y strainer manufacturers in Saudi Arabia. A Y strainer, also known as a Y filter, is an essential device used in various fluid-handling applications to remove unwanted solid particles from liquid, gas, or steam systems.

Working Mechanism:

1)The Y strainer’s strainer leg slopes downwards when inserted into the pipeline.

2)Internal screen catches solid particles as fluid passes through the body, only allowing clean fluid to pass through.

3)Remove the screen or utilize the blow-off plug in order to clean accumulated debris.

Benefits of Using Y Strainer:

1)Space-saving design that can be installed horizontally or vertically.

2)Low pressure decline.

3)Easy to clean and maintain.

4)Reliable and affordable.

Industries:

1)Gas and Oil

2)Chemical

3)Power production

4)Water treatment

Key Components of Y Strainer:

1)Body: Carbon steel, stainless steel, or cast iron is used to make them.

2)Blow-off Plug/Drain: This design facilitates easy cleaning without disassembly.

3)Cover/ Cap: The strainer screen is accessible through the cover or cap.

Description:

Body: Carbon Steel, CF8, CF8M, CF3M, Cast Iron, SS304, SS316, SS304, SS304L, SS316, SS316L

Class: 150-2500

Nominal Pressure: PN6- PN450

Size: ½” to 24”

Ends: Buttweld, Flanged, Socket weld, Threaded.