- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

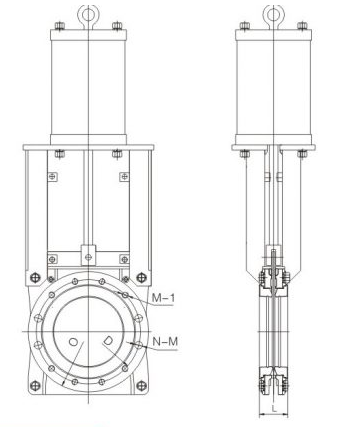

Slurry Knife Gate Valve Manufacturers in Saudi Arabia: Heavy-Duty Flow Control

Middleeast valve is a top Slurry Knife Gate valve manufacturer in Saudi Arabia. These valve are designed to handle. Slurries, which are thick mixes of solids suspended in a liquid.

Major Components:

- Knife Gate: A hardened blade which slices solid-laden fluids

- Valve Body: Constructed from long-lasting materials such as stainless steel or ductile iron

- Seats and Seals: Formed to withstand wear and provide leak-proof sealing

- Purge Ports: Prevent material to accumulate in valve body

- Actuator: Hand, pneumatic, or electrical for simple actuation

Working Mechanism:

On actuating the actuator, the knife gate travels vertically along the path of flow. It cuts through solids and slurry, and provides full shut-off when in closed position. The self-cleaning design of the valve along with purge ports avoids clogging and wear and tear, hence can be continuously operated.

Benefits:

- Efficiently handles abrasive and high-viscosity media

- Non-clog design with purge options

- Corrosion- and erosion-resistant, as well as abrasion-resistant

- Multi-actuation type options

- Long equipment life with minimal maintenance

Industries:

- Mining

- Wastewater Treatment

- Pulp and Paper

- Chemical Processing

- Power Generation

- Oil and Gas Industry

- Petrochemicals

Description:

Available materials: CF8M, SS2507, SS316, SS304, CF8, Ductile Iron, WCB, WC6, WCC, LCB, LCC, Cast iron,

class:150-600 PN6to PN25

size:2”-24”

Operation: Hand wheel, Gear operated, electric actuated ,pneumatic actuated

Ends : Lug, Wafer, Flanged