- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

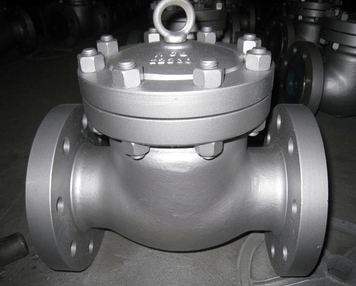

Titanium Swing Check Valve

Middleeast Valve is a world-class manufacturer and global supplier of high-tech valve solutions for corrosive and harsh environments. Our Titanium Swing Check Valve is constructed with precision engineering and corrosion-resistant titanium to provide maximum reliability and protection against reverse flow in fluid systems.

Definition

A Titanium Swing Check Valve is a check valve that permits fluid to travel in one direction only and automatically prevents backflow. It functions with a hinged disc that swings open on forward flow and closes upon reversal of flow, providing a straightforward, efficient means of safeguarding piping systems.

Principal Components

- Body: Constructed of Titanium (usually Grade 2 or Grade 5) for high corrosion resistance

- Disc: Flap that opens on the flow

- Seat Ring: Sealing surface for the disc

- Hinge Pin & Arm: Attaches the disc to the body and permits movement

- Bonnet/Cover: For internal components access

- Seals/Gaskets: Leak-tight operation ensures

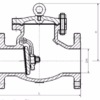

Working Mechanism

When flow is in the forward direction, pressure lifts the disc so free flow can happen. If there is a reversal of flow, the disc will swing back and sit on the seat, occluding the flow and avoiding backflow. It is a passive system that has no need for manual or electric operation and hence is well-suited for automatic protection.

Advantages

- High corrosion resistance in seawater, chlorides, and hostile chemicals

- No electricity or manual control needed

- Protects against pumps, compressors, and pipelines damage

- Low pressure drop and low maintenance

- Reliable in both horizontal and vertical orientations

Industries Served

- Marine and Offshore Engineering

- Chemical and Petrochemical Plants

- Desalination and Water Treatment

- Biotech Industry

- Oil & Gas