- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

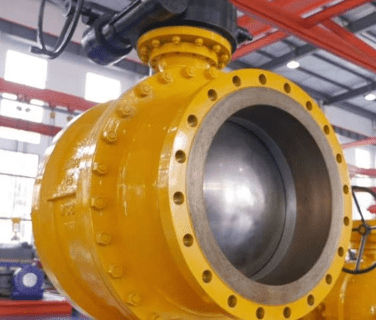

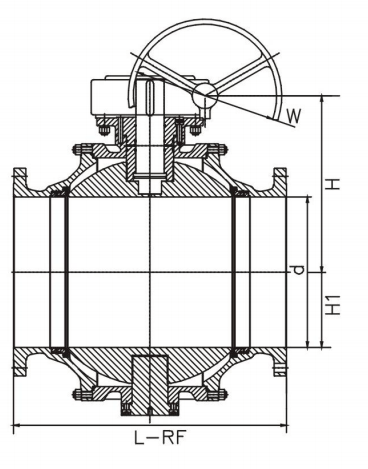

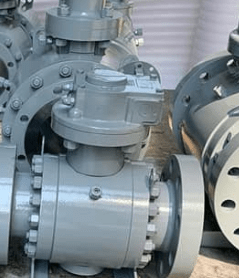

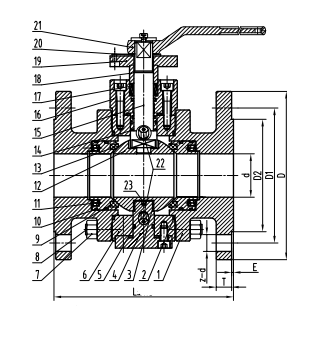

Trunnion Ball Valve Suppliers in Saudi Arabia: High-Pressure Flow Control Solution

Middleeast Valve is a leading Trunnion ball valve suppliers in Saudi Arabia. It is a support that holds the ball in place in a valve. It can be operated manually or with actuators and is designed for bidirectional flow.

Key Components:

- Valve Body: The main structure that houses internal components

- Trunnion-Mounted Ball: Fixed ball which rotates within the valve body

- Seats: Spring-loaded or pressure-loaded seats for tight closure

- Stem: Connects ball to actuator or handle

- Seals and Gaskets: Ensure leak-tight operation

- Trunnion: Stabilizes and supports the ball

Working Mechanism:

In a trunnion ball valve, the ball is stationary and the stem rotates it. The trunnion supports bear the pressure of the flow, and the seats are pushed against the ball by springs or line pressure. Low torque with smooth operation is offered even in high-pressure applications.

Advantages:

- Lower operating torque compared to floating ball valves

- Good sealing, even at high pressure

- Suitable for large-diameter pipelines

- Reliable performance at high temperature and low temperature

- Long life with low maintenance

Industries Served:

- Oil and Gas Industry

- Petrochemical Industry

- Power Generation

- Water and Wastewater Treatment

- Mining Industry

- Chemical Industry.

- Marine Industry

Description:

Body Material: Cast steel (WCB, WCC, WC6, LCC, LCB), Stainless steel (SS316, SS304, F51, F55, CF8, CF8M), Titanium.

Size: 2” to 48”

Class: 150 to 2500; PN16 to PN450

Ends: Buttweld, Socket weld, Flanged

Operations: Gear Operated, Electric Actuated, Pneumatic actuated, Lever