- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

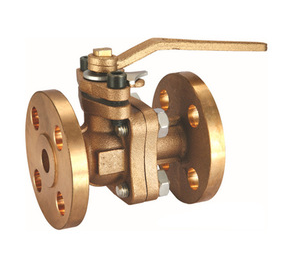

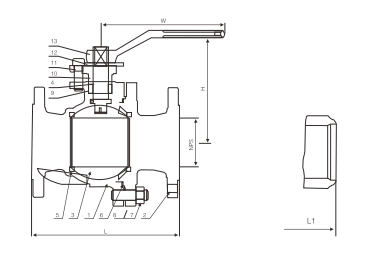

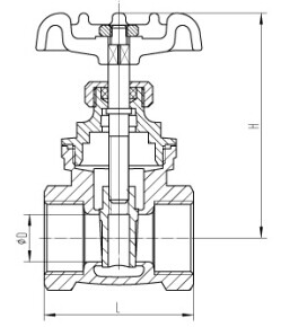

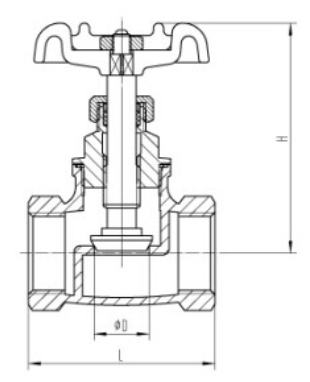

Bronze Valve Supplier in Saudi Arabia: Durable and Cost-Effective Flow Control

Middleeast valve is the top Bronze valve supplier in Saudi Arabia. Bronze valves are critical components used in various piping systems to control the flow of fluids such as water, oil, gas, and steam.

Types:

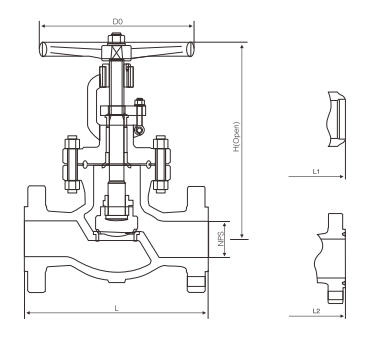

- Bronze globe valve

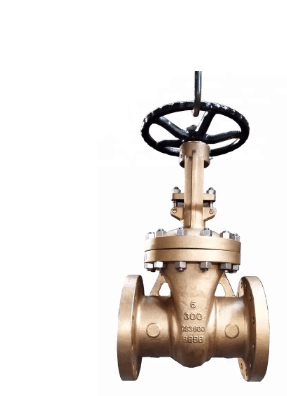

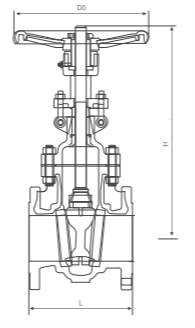

- Bronze gate valve

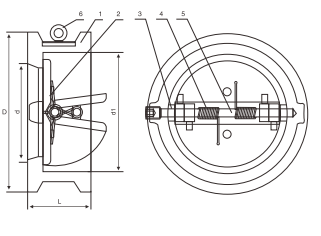

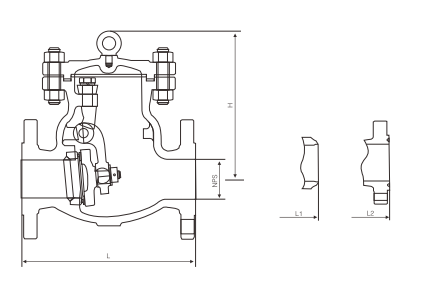

- Bronze check valve

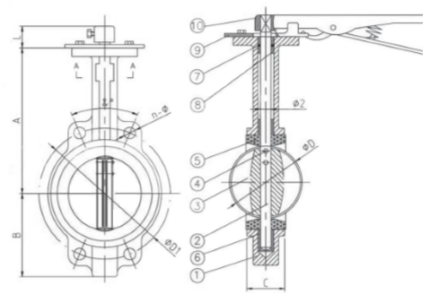

- Bronze butterfly valve

- Bronze ball valve

Functions:

- Flow Control

- Pressure Regulation

- Backflow Prevention

- Safety

Industries:

- Plumbing and water supply systems

- Oil and gas

- Marine and shipbuilding

- Chemical processing

- Fire protection systems

- Irrigation and agriculture

Description:

Body material- Bronze (CAC401,CAC406), B148 C95800, CAC401,CAC406,SS304, SS904, SS904L, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Incoloy, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron, super duplex

Class- 150-2500

Ends- Flanged, wafer, lug, Buttweld, threaded

Size-1/2’’- 4’’

Operations- Pneumatic actuated, Electric Actuated, Gear Operated, Lever Operated, Handwheel Operated