3 Piece Ball Valve

Middleeast valve is the leading 3 piece ball valve supplier in Saudi Arabia. A ball valve is a quarter-turn valve that uses a hollow, perforated, and pivoting ball to control the flow of a liquid or gas. The ball’s position determines whether the valve is open or closed. When the ball’s hole is in line with the flow, the valve is open, allowing the fluid to pass through. When the ball is rotated 90 degrees, the hole is perpendicular to the flow, and the valve is closed, blocking the passage.

Meaning of 3 Piece Ball Valve:

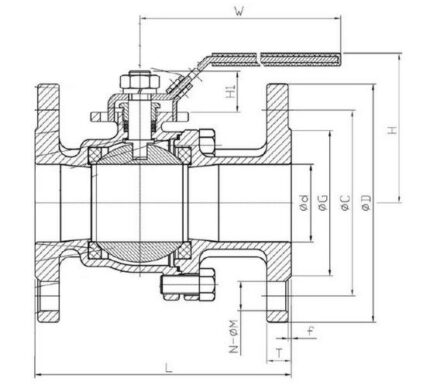

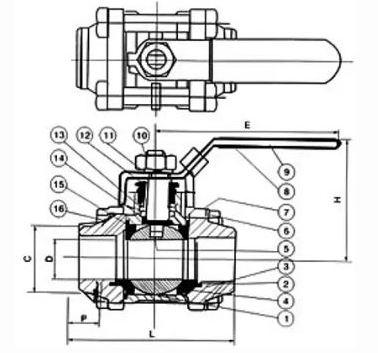

A 3 piece ball valve is an advanced variation of the standard ball valve. It consists of three main parts: two end caps and a central body. These parts are connected by bolts or threaded fasteners. This construction allows for easier maintenance, as the central body can be removed without disturbing the piping system. This design is especially beneficial in applications where frequent cleaning or replacement of the valve is required.

Working of a 3 Piece Ball Valve:

The working principle of a 3 piece ball valve is similar to that of other ball valves but with enhanced maintenance capabilities. Here’s a step-by-step overview of its operation:

- Flow Control: The valve has a ball with a hole through the center. When the handle or actuator turns the ball, the hole aligns with the pipe, allowing fluid to flow through.

- Sealing: When the ball is turned 90 degrees, the solid part of the ball blocks the flow. The seals around the ball ensure a tight closure, preventing any leakage.

- Maintenance: Unlike one-piece or two-piece ball valves, the 3 piece design allows for the removal of the central body without disconnecting the end caps from the pipeline. This feature facilitates easy access for cleaning, repair, or replacement.

Functions of a 3 Piece Ball Valve:

The primary function of a 3 piece ball valve is to regulate the flow of fluids. It can be used to:

- Start or Stop Flow: The valve can quickly open or close the flow with a 90-degree turn.

- Throttle Flow: Although not ideal for precise flow control, it can be used to adjust the flow rate in some applications.

- Divert Flow: Some 3 piece ball valves are designed with multiple ports to divert flow from one pipeline to another.

Middleeast valve is well known for 3 piece ball valve supplier in Saudi Arabia and its unique design allows for quick servicing and minimal disruption, making it an excellent choice for industries that require efficient and durable flow control solutions.

Description:

- Available materials: Cast iron, WCB, WCC, WC6, LCC, LCB, Titanium, SS304, SS316, CF8, CF8M, F55, F51, F53, Monel, Ductile Iron.

- PN- PN10 to PN450

- Class: 150-2500

- Size: 1/2”- 48”.

- Operations: Lever operated ball valve, electric actuated ball valve, pneumatic actuated ball valve, gear operated ball valve

- Ends: Flanged, Butt weld, Socket weld, Threaded