- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

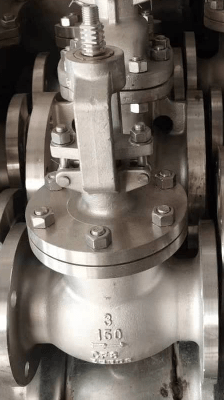

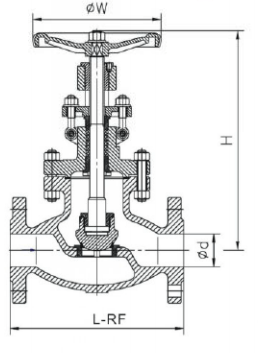

Stainless Steel Globe Valve Manufacturers in Saudi Arabia: Durable Flow Control

Middleeast is the greatest Stainless steel globe valve manufacturers in Saudi Arabia. It is valve which control flow of fluid by pipeline. Made from superior quality stainless steel, these valves are specially designed for application where strength, corrosion resistance, and durability are utmost considerations. Globe valve has a spherical body having an internal baffle which controls the flow of fluids, often used for throttling or blocking particular elements of a system.

Key Parts of a Stainless Steel Globe Valve

- Body

- Disc

- Stem

- Seat

- Handle

- Bonnet

- Gasket

How it works:

The Stainless Steel Globe Valve operates by moving the disc up and down to regulate the flow of fluids. When in the open position, the disc is pushed away from the seat to allow fluid to pass through. When in the closed position, the disc is forced against the seat, stopping flow. This allows for precise control of the flow, especially in throttling and flow isolation service.

Advantages of Stainless Steel Globe Valve

- It is corrosion-resistant

- It is durable and robust

- It is durable

- Easy to clean and maintain

Applications of Stainless Steel Globe Valve

- Oil and gas

- Petrochemical

- Power generation

- Water treatment

- Chemical processing

- Marine