- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

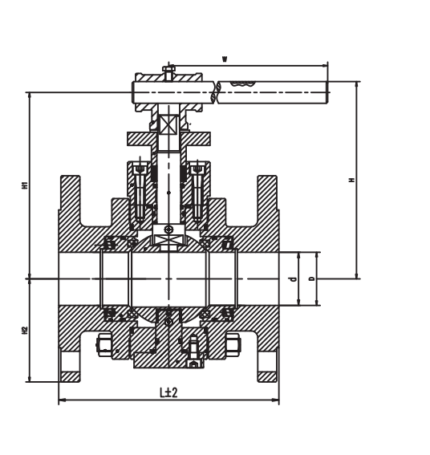

Alloy Trunnion Ball Valve

Middleeast Valve is the top supplier of Alloy Trunnion Ball Valve specifically engineered for high pressure operation in industries requiring precision and reliability. With heavy duty alloy construction these valve provide higher strength, durability and corrosion resistance which make them the best option for harsh environment.

Definition

Alloy Trunnion Ball Valve is the ball valve whose ball is held by a trunnion (fixed bearing) on either side. This configuration minimize the torque that has to be applied to open or close the valve while providing tight sealing which is ideal for high pressure system. The alloy structure offer superior corrosion and wear resistance in harsh environment.

Key Parts

- Valve Body: Made from high performance alloy such as stainless steel, Inconel or Monel to provide greater strength and resistance to corrosion.

- Trunnion Mounted Ball: A fixed ball mounted on trunnion on both side minimizing torque and providing stability.

- Seats and Seals: Provide a tight closure when the valve is in a closed position, usually constructed from hard elastomers or PTFE.

- Actuator: The pneumatic, electric, or manual actuator that turns the valve in order to regulate the flow.

- Stem: Links the ball to the actuator to allow the rotation of the ball.

Working Mechanism

In the Alloy Trunnion Ball Valve- the actuator rotate the ball mounted on the trunnion to open or close the valve. The fixed support of the ball assure minimum wear and tear, with the result that the torque is reduced and there is smooth operation, even when the system is under high pressure. The seat of the valve are pressed hard onto the ball to assure a tight seal when the valve is shut.

Advantages

- Improved performance under high-pressure conditions

- Lower torque operation for ease of handling

- Excellent erosion and corrosion resistance

- Long lifespan with low maintenance

- Tight shut-off and leak-free sealing with high reliability

Industries Typically Used in:

- Oil & Gas

- Petrochemical

- Power Generation

- Water Treatment

- Chemical Processing