- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Thermodynamic Steam Trap Suppliers in Saudi Arabia: Compact and Efficient Steam Control

Middleeast Valve is the top Thermodynamic Steam Trap Suppliers in Saudi Arabia offers durable, compact, and extremely efficient steam traps for high-pressure use. Because of their low maintenance level and high strength, these steam traps are exactly engineered to be able to support an extremely broad range of operating conditions.

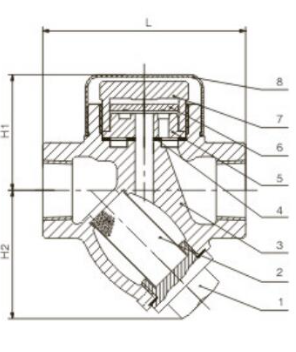

Key Components of Thermodynamic Steam Trap:

- Disc: The central moving part which opens and closes upon pressure fluctuation.

- Body: Typically made up of stainless steel or forged.

- Cover Plate: The disc is supported by the cover plate.

- Cap and Seat: It sustain the disc and direct the steam flow.

Working Mechanism:

The dynamic motion of flash steam is the foundation of the functioning of thermodynamic steam traps. The disc moves up as condensate enters, allowing discharge. The disk closes with a snap as steam enters due to the pressure and velocity difference. It is ideal for fluctuating loads since the cycle repeats whenever condensate builds up again.

Advantages of Using Thermodynamic Steam Trap:

- Simple and compact design

- Ideal for high-pressure and superheated steam

- Little maintenance

- Resists rust and freezing

- Functions in any role

Functions of Thermodynamic Steam Trap:

- Properly releases condensate

- Prevents loss of steam

- Removes gasses and air

Industries:

- Gas and Oil

- Petrochemical and Chemical

- Power Plants

- Refinement

- Textile Sector

Description:

Body Material: Carbon steel, Ductile iron, Stainless steel (SS304, SS316), Cast iron, Forged steel (A105, F11, F22)

Size: 1/2″ to 2″

Nominal Pressure: PN10 to PN250

Class: 150 to 300