CRYOGENIC GATE VALVE SUPPLIER IN BAHRAIN

Middleeast valve is famous for Cryogenic gate valve supplier in Bahrain. It is used in industries such as liquefied natural gas (LNG) production, aerospace, medical and scientific research, and any other applications that involve the handling and transportation of cryogenic liquids or gases.

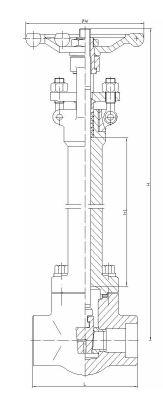

The primary function of a valve is to control the flow of cryogenic fluids. It does this by using a gate-like disc or wedge that can be moved up and down to either block or allow the flow of the fluid through the valve. When the gate is fully lowered, the valve is in the closed position, and no fluid can pass through. When the gate is fully raised, the valve is in the open position, allowing for unrestricted flow.

Working principle:

- Valve Body: the valve consists of a body that contains the fluid passageway.

- Gate/Wedge: inside the valve body, there is a gate or wedge-shaped element that can be raised or lowered within the flow path.

- Actuator: to control the position of the gate, cryogenic gate valves are equipped with an actuator.

- Sealing Mechanism: these seals are typically made from materials that remain flexible and reliable in cryogenic conditions.

- Operation: to operate the valve, the actuator is manipulated to either raise or lower the gate.

Advantages:

- Cryogenic gate valves are specifically designed to operate at extremely low temperatures, making them suitable for use in cryogenic systems.

- These valves have a tight seal that prevents leakage, even at low temperatures.

- They are typically made of materials that are resistant to extreme cold and corrosion, making them durable and long-lasting.

- They are easy to operate, with simple manual or powered mechanisms, such as a handle or wheel, that can be used to open or close the valve.

Industries:

- Aerospace Industry

- Energy Plants

- Industrial Gases

- Marine Industry

Description:

- Available materials: SS306, SS904, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Incoloy, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron

- Size: 1/2″- 64”

- Class: 150 to 2500

- Nominal Pressure: PN10 to PN450

- Operation: Hand Wheel, Gear operated, Electric and Pneumatic Actuated

- Ends: Flanged, Buttweld, Socketweld, Threaded

- Standards: ASME, API6D, API607, DIN, BS, ANSI, AWWA