- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

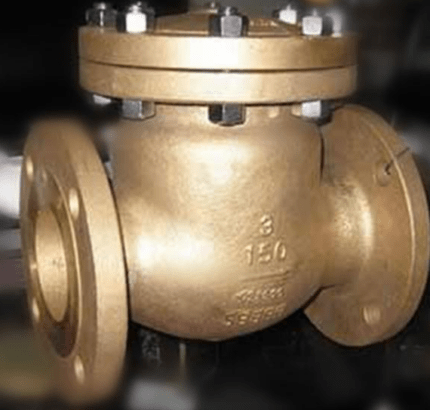

Aluminium Bronze Swing Check Valve

Middleeast Valve is a reliable producer and international distributor of high-performance industrial valves that provide robust and corrosion-resistant flow control solutions. Our Aluminium Bronze Swing Check Valve is specifically developed to stop backflow in piping system promoting secure and efficient operation in corrosive condition.

Definition

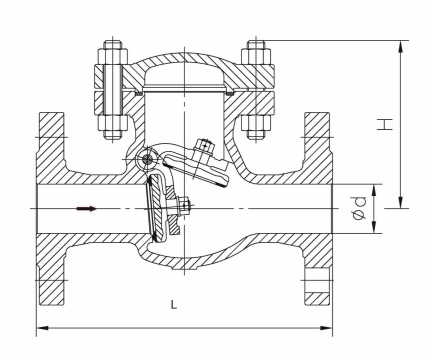

An Aluminium Bronze Swing Check Valve is a check valve that permit fluid to flow in one direction only. It incorporates a swinging disc mechanism that opens on forward flow and automatically closes when flow reverses, stopping backflow.

Key Parts

The main constituent are the aluminium bronze body, swing disc, hinge pin, cover and seat ring. Aluminium bronze which has high corrosion resistance and strength is suitable for applications in seawater, chemical and high pressure environment.

Working Mechanism

When fluid flow in the desired direction, pressure pushes the disc away from the seat to permit flow. When flow reverses, the disc closes back and sits on the seat, shutting the valve. Automatic action prevents maximum pressure loss and shuts off reverse flow effectively.

Benefits

- Good corrosion resistance in seawater and aggressive fluids

- Consistent backflow prevention without manual operation

- Long-lasting, with little maintenance requirement

- Accepts horizontal or vertical mounting

- Low pressure drop and low noise operation

Applications

Used in marine, offshore, desalination, oil & gas, chemical processing, and water treatment plants.

Why is it Needed?

The valve is necessary to protect equipment and ensure unidirectional flow in systems exposed to corrosive liquids and changing pressures.

Why Customers Should Purchase from Us?

Middleeast Valve offers high-quality valves precision-built and performance-tested. We offer competitive pricing, quick delivery, and superior customer service for each and every project.