- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

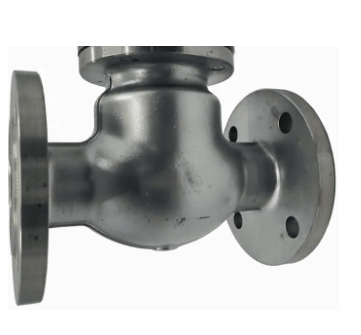

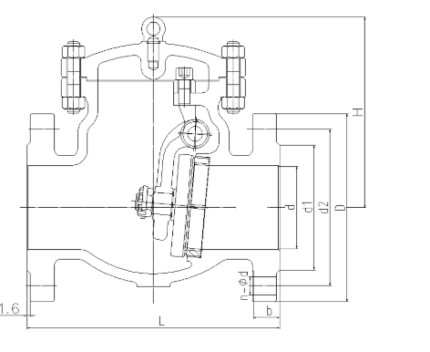

Alloy Swing Check Valve

Middleeast Valve is the leading Manufacturer of Alloy Swing Check Valve. We proudly present best quality Alloy Swing Check Valve designed to avoid backflow in piping systems at severe temperature and corrosive conditions. Such valve are highly regarded for their strong construction, high reliability, and easy maintenance feature, which makes them a vital component in numerous industrial applications.

Definition

Alloy Swing Check Valve is type of non return valve that allow fluid to flow in one direction only. It feature the disc that swing open with forward flow and automatically close when the flow reverse preventing backflow and potential system damage.

Key Parts

- Valve Body: Made from high performance alloy such as Inconel, Hastelloy or Monel for corrosion and heat resistance.

- Disc: The swinging component that opens and closes based on flow direction.

- Hinge Pin: Connects the disc to the valve body and allows it to pivot.

- Seat: Provides a tight seal when the disc closes to prevent reverse flow.

Working Mechanism

During forward flow, the pressure pushes the disc open, allowing fluid to pass. When the flow reverses or drops, the disc swings shut under gravity or backpressure, sealing against the valve seat and stopping backflow.

Advantages

- Prevents reverse flow and protects equipment

- Durable under high pressure and temperature

- Resistant to corrosion and chemical attack

- Low maintenance with simple operation

- Long service life in harsh environments

Industries Used in:

- Oil & Gas

- Petrochemical

- Power Generation

- Marine

- Chemical Processing

Why is it Required?

It ensures unidirectional flow, protects pumps and compressors, and enhances system safety in aggressive service conditions.

Why Buy from Us?

Middleeast Valve offers top-grade valves with material certifications, precise manufacturing, competitive pricing, and technical expertise to support any project need.