- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

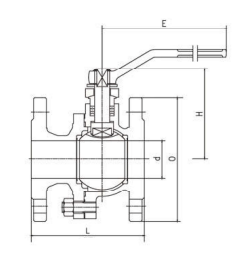

Duplex Floating Ball Valve

Middleeast Valve is the foremost supplier of high quality flow control solutions aimed at performing within hostile industrial applications. Our Duplex Floating Ball Valve is manufactured for durability, corrosion resistance and maximum sealing performance in heavy duty and high pressure system in any industry.

Definition

A Duplex Floating Ball Valve is a quarter-turn valve made of duplex stainless steel that is used to offer tight shut-off with a floating ball mechanism. The ball is retained by two valve seat and is able to float slightly under pressure which improve sealing reliability. The duplex stainless steel material provide an ideal combination of corrosion resistance and mechanical strength.

Key Parts

- Valve body

- Floating ball

- Stem

- Seat ring

- Seal

- Actuator

Working Mechanism

When the actuator or handle is rotated 90 degrees, the ball is turned in the valve body to open or shut the flow path. The “floating” action of the ball enables it to contact the downstream seat under pressure to provide a tight seal.

Advantages

- Excellent erosion and corrosion resistance

- Good mechanical strength for high-pressure service

- Compact, uncomplicated design with low maintenance

- Low torque sealing with tight closure

- Applicable for corrosive and aggressive media

Industries Served

- Oil & gas

- Chemical and petrochemical

- Marine and offshore

- Water treatment

- Power generation

Why Is It Necessary?

Duplex Floating Ball Valve play an essential role where high pressure and corrosive fluid is involved in the operation. Its leak tightness guarantee safe operation and system integrity.

Why Purchase from Us?

Middleeast Valve offers international-standard valves tested strictly. Technical assistance, express delivery, and customized solutions designed according to your specific needs are provided by our experts.