- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

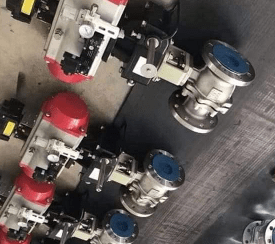

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

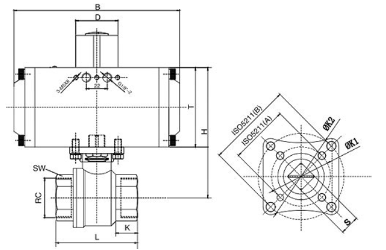

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

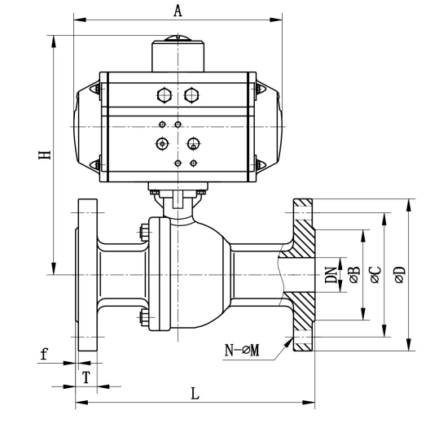

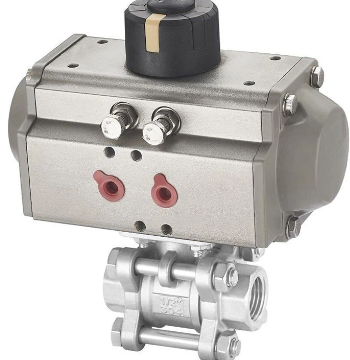

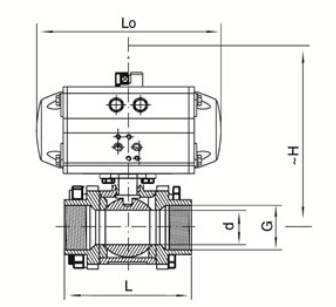

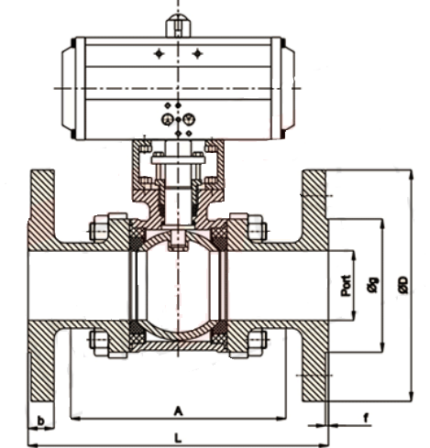

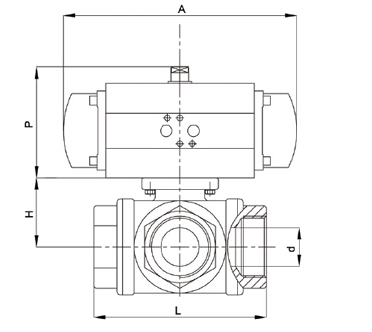

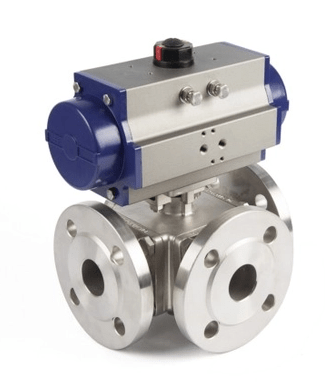

Pneumatic Actuated Ball Valve Supplier in Riyadh: Fast and Efficient Flow Control

Middleeast Valve is the largest Pneumatic Actuated Ball valve supplier in Riyadh. The valve consists of a sphere having a hole or port through it that may be rotated to allow or prevent the flow of liquids.

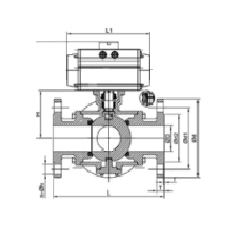

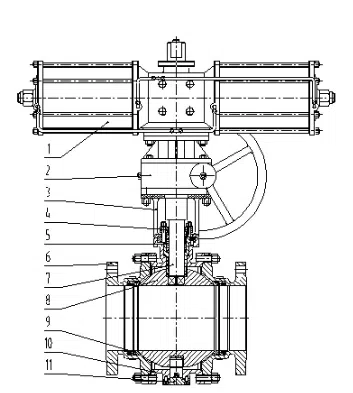

Key Parts of Pneumatic Actuated Ball Valve:

- Valve Body: Constructed from carbon steel, stainless steel, or other durable materials

- Ball with bore: For opening or closing the flow, the ball with the bore rotates.

- Seats and Seals: Make sure they seat firmly.

- Stem: The ball and the stem are attached to the actuator.

- Pneumatic Actuator: A pneumatic actuator uses compressed air to control the valve.

Working Mechanism:

The ball is turned 90 degrees through the stem by the pneumatic actuator through compressed air. Opening or closing of the valve is done with this rapid action, allowing or preventing fluid flow. Based on the requirements for control, the system can be either single-acting (spring return) or double-acting.

Advantages of Using Pneumatic Actuated Ball Valve:

- Rapid and reliable operation

- Best suited for high-cycle and high-pressure systems

- Safe for hazardous applications and explosion-proof

- Energy-efficient and minimal maintenance

- Easy integration of control system

Industries:

- Water and Wastewater Treatment

- Oil and Gas

- Mining

- Chemical Industry

Description:

Body: Cast Iron, Cast steel (WCB, WCC, WC6, LCC, LCB), Carbon steel (CF8, CF8M), Titanium, Stainless steel (SS304, SS316, A105, F304, F304L, F316, F316L).

Class: 150-2500, PN 10 – PN450.

Size: ½” to 48”.

Ends: Socket weld, butt weld, flanged, threaded .

Operation: Pneumatic actuated.