- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

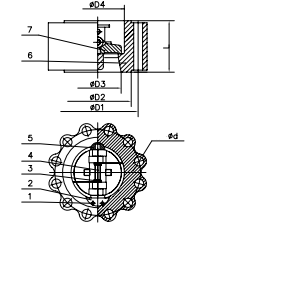

Dual Plate Lug Check Valve Suppliers in UAE: Compact Solution for Backflow Prevention

Middle East Valve is a well known Dual Plate Lug Check valve suppliers in UAE. It is a check valve that is used to avoid backflow in a piping system. It consists of two spring-loaded plates (or discs) that close automatically in case of a reversal of flow. The lug-type body enables simple installation between flanges using bolts, making it ideal for close or limited-space systems.

Components:

- Valve Body (Lug Type) – made for simple bolting between pipe flanges

- Dual Plates/Discs – swing open on forward flow and close on reverse flow

- Spring Mechanism – provides fast and positive closing action

- Seat – ensures leak-tight sealing

- Stop Pin and Hinge – direct the plates’ movement

Working Mechanism:

When fluid moves in the proper direction, pressure opens the two plates. When flow ceases or reverses, the springs cause the plates to return to the closed position, thus avoiding backflow. The spring-aided construction provides quick response time and reduces water hammer and is thus suitable for use in variable flow conditions in systems.

Advantages:

- Lightweight, small in size, and easy to install

- Avoids backflow and safeguards pumps and equipment

- Lug design facilitates simple removal and maintenance

- Low pressure drop due to streamlined design

- Corrosion-resistant and appropriate for harsh environments

Industries We Serve:

- Oil & Gas

- Water and Wastewater

- Chemical and Petrochemical

- Power Generation

- Marine and Shipbuilding

- HVAC Systems

- Mining

- Fire Protection

Description:

Body Material: Cast Iron, Ductile Iron, Cast Steel, Stainless Steel, Aluminium Bronze

Disc: Ductile Iron, Stainless Steel, Aluminium Bronze

Size: DN50 to DN900

Nominal Pressure: Class 150 to Class 2500