- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

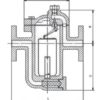

Inverted Bucket Steam Trap Supplier in Kuwait: Durable Steam Control

Middleeast Valve is the largest Inverted Bucket Steam Trap Supplier in Kuwait. It is a type of mechanical steam trap that is widely used in industrial applications to remove condensate, air, and non-condensable gases from steam systems.

Key Components of Inverted Bucket Steam Trap:

- Inverted Bucket: Floats to control valve action.

- Valve and Seat Assembly: It controls the discharge.

- Body: Made of ductile iron, stainless steel, or cast steel.

- Air Vent: Facilitates the expulsion of air when starting.

Working Mechanism:

The inverted bucket floats when steam reaches the trap, closing the valve and stopping the steam from escaping. The bucket loses buoyancy as the condensate accumulates, sinks, and the valve opens to discharge the condensate. Based on the condition of the system, this cycle is repeatedly repeated.

Advantages of Using Inverted Bucket Steam Trap:

- Reliable operation under challenging conditions

- Water- and dirt-proof hammer

- Longer life of service

- Effectively manages the evacuation of air and condensate

- Ideal for steam that has been superheated

Functions of Inverted Bucket Steam Trap:

- Condensate is removed without releasing steam.

- Releases gasses that are not condensable.

- Keeps the system operating efficiently.

Industries:

- Gas and Oil

- Petrochemical

- Paper and Pulp

- Power Plants

Description:

Body Material: Carbon steel, Ductile iron, Stainless steel (SS304, SS316), Cast iron, Forged steel (A105, F11, F22)

Size: 1/2″ to 2″

Nominal Pressure: PN10 to PN250

Class: 150 to 300