Check Valve

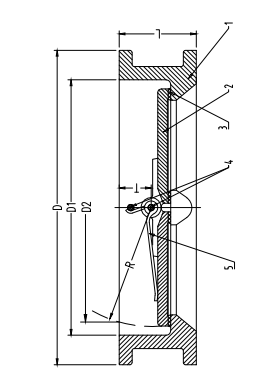

Middleeast valve is the greatest Check Valve Suppliers in UAE. It is also known as a non-return valve or one-way valve. It consists of a valve body or housing, which contains the internal components of the valve and is designed to operate in a specific flow direction. They have an inlet port (where fluid enters) and an outlet port (where fluid exits). Inside the valve body, there is a movable mechanism, such as a flap, disc, or ball.

What is the function of the check control valve?

The check control valve serves as a crucial component in various systems, particularly in plumbing and fluid dynamics. Its primary function is to regulate the flow of fluids or gases in a single direction, preventing backflow or reverse flow. By allowing fluid or gas to pass through in one direction while blocking it in the opposite direction, the valve ensures proper system operation and prevents contamination or damage.

Types:

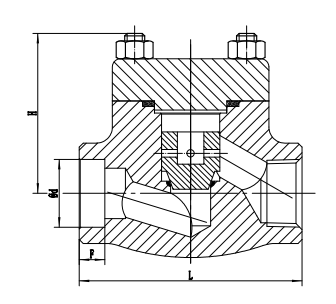

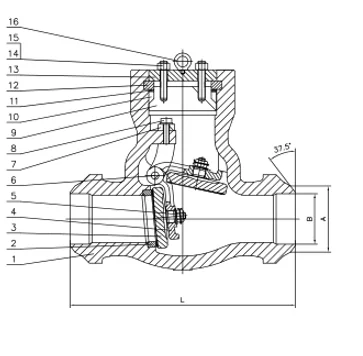

- Swing check valve

- Ball check valve

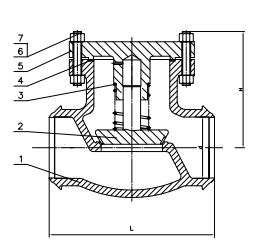

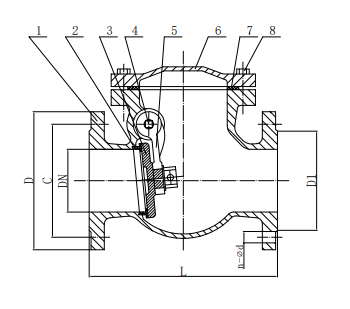

- Lift check valve

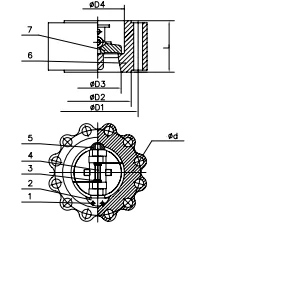

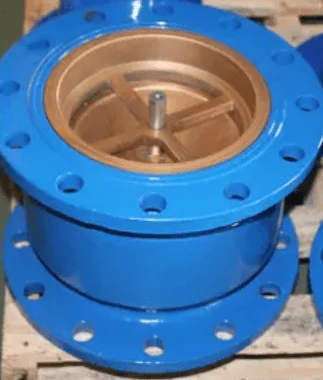

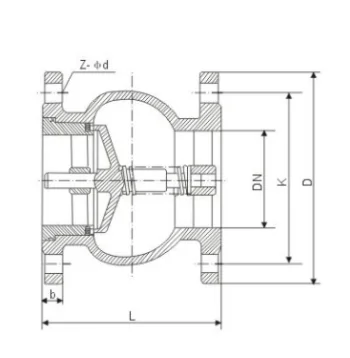

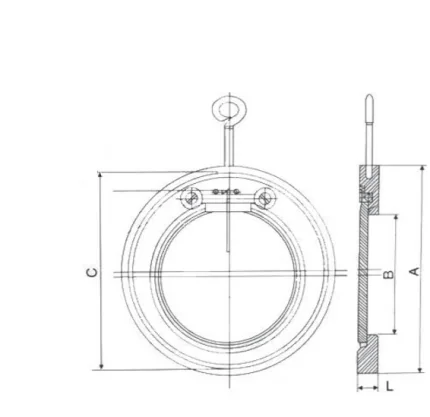

- Dual plate check valve

- Single Plate check valve

- Non slam swing check valve

- Tilting disc check valve

- Pressure seal check valve

- Foot Check valve

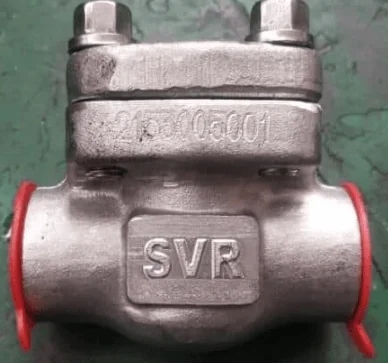

- Forged Steel Check Valve

Advantages:

- Prevent backflow

- Simple design and operation

- Low maintenance

Industries:

- Chemical Industry

- Pulp and paper Industry

- Marine Industry

- Mining Industry

- Power Generation Industry

- Oil and Gas Industry

- Nuclear Industry

- Petrochemical Industry

- Water Treatment Plants

- Textile Manufacturing Industry

Description:

- Body Material- Cast Iron and Cast Steel (LF2, A216, WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F91), DUPLEX AND Super duplex STEEL [ F51, F53,F55 ] Forged Steel A105, A105N, F11, F22, F304, F316, F91] , Alloy20 , Hastelloy ALBR.

- Size- ½” – 80”

- Class-150 – 2500; PN10 – PN-450

- Ends- Threaded, socket weld, butt weld, flanged, lug, wafer.