- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

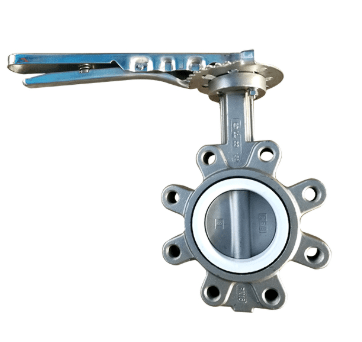

Alloy Lug Butterfly Valve

Middleeast Valve is one of the top Alloy Lug Butterfly Valve Supplier.We provide valve for precise flow regulation and system isolation. Made from high-quality alloy materials, these valves provide high performance in extreme environments, with consistent operation in multiple industrial applications where durability and corrosion resistance are significant.

Definition

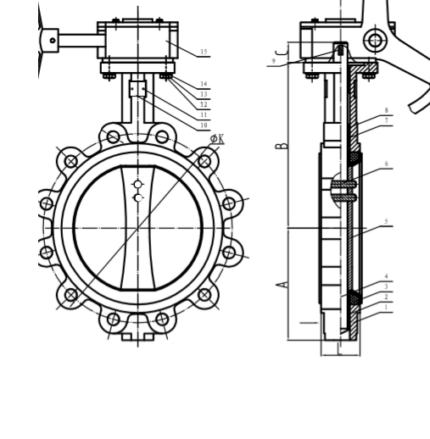

An Alloy Lug Butterfly Valve is a quarter turn valve which employs a round disc loaded on a shaft for flow regulation. The lug construction facilitate mounting and demounting of the valve without disconnecting the pipeline. Constructed with strong alloy material- these valve are ideally suitable for high strength and corrosion resistant application.

Major Components

- Valve Body: Composed of high-performance alloys such as stainless steel or Inconel with high corrosion resistance.

- Disc: A turning disc that controls the flow by opening or closing the valve.

- Stem: Secures the disc to the actuator and permits it to turn.

- Lug Design: Allows the valve to be bolted between two pipe flanges, permitting leak-proof, secure connections.

- Seal/Seat: Typically made of elastomers such as EPDM or PTFE to create tight sealing.

Working Mechanism

The Alloy Lug Butterfly Valve functions through the turning of the disc by 90 degrees using an actuator to enable or prevent flow. Lug structure allows the valve to be readily installed or substituted without unbonding the pipeline. Seal from the valve maintains a complete shut-off so as not to leak when closing the valve.

Benefits

- Easy to install and maintain owing to lug structure

- Slim and space-saving design

- Better corrosion and heat resistance

- Fast and effective operation with 90-degree rotation

- Low pressure drop and energy conservation

Applications Suitable for application in:

- Water & Wastewater Treatment

- Oil & Gas

- Chemical Processing

- HVAC Systems