- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

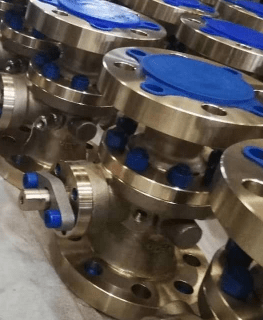

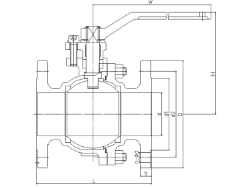

CASTING FLOATING BALL VALVE

Middleeast Valve is one of the leading manufacturer and supplier of high quality valve. With us at Middleeast Valve, you can get premium valve solutions, which can also meet the demand of industries on a global platform. Our Casting Floating Ball Valve is one among the most tried and tested valve that is preferably used to modulate the pressure of fluids as well as gas in various industries. This valve is manufactured by using the highest-grade materials to ensure precision work, low maintenance, and even maximum performance within low and high-pressure applications.

Key Component

- Body: Made of durable cast materials, providing structural integrity and high-pressure resistance.

- Ball: A spherical component with a passage that moves to control the fluid flow.

- Stem: The stem connects the ball to the actuator, controlling the rotation of the ball.

- Seals: Ensure close sealing to prevent any leakage upon closing the valve.

Working Principle

Floating Ball Valve is driven by rotating the ball inside the valve body. With the ball open position, the hole lines up with the pipeline, and the fluid will pass through. On rotating the valve to close the position, the ball moves to a seat that actually restricts the flow. The floating ball design enhances sealing, especially under high pressure.

Advantages

- Reliable Sealing: The floating ball design offers a positive, leak-free seal.

- Long-Enduring: Cast materials provide superior wear resistance, corrosion resistance, and high pressure resistance.

- Easy Maintenance: Simple disassembly for maintenance makes it convenient.

- Cost-Effective: Offers long-term reliability without other types of valve’s high cost of maintenance.

Industries

- Water treatment

- Oil and gas

- Chemical processing

- HVAC system

- Power generation