- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

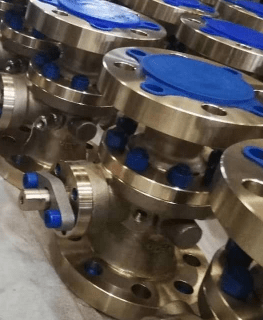

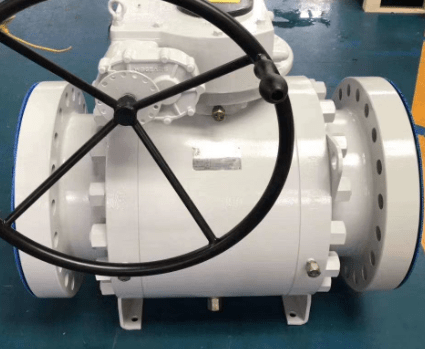

Floating Ball Valve Suppliers in UAE: Efficient Sealing for Versatile Flow Control

Middleeast Valve is a reputed Floating ball valve suppliers in UAE. The valve comprises of a ball that can freely move or “float” inside the valve body and has a hole running through its center.

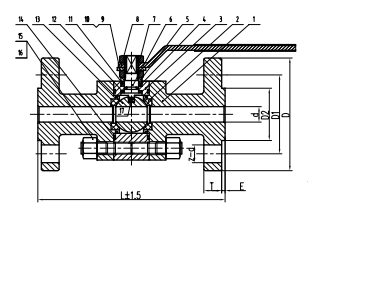

Key Components of Floating Ball Valve:

- Ball: The floating ball is supported between seats in order to realize tight sealing.

- Valve Body: The body of the valve is a cast or forged unit that contains internal components.

- Seats: Ensure sealing on both sides to avoid leakage.

- Stem: Connecting the handle or actuator to the ball is the stem.

- Actuator/Handle: For automatic or manual use

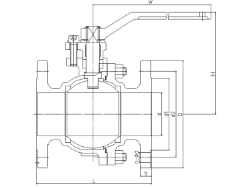

Working Mechanism:

The ball in a floating ball valve can travel some but is restrained by the valve seats that compress.

The ball pushes against the downstream seat when it is pressured, tightly closing the valve and preventing fluid leaks.

This design is suitable for pipes that are small to medium size.

Advantages of Using Floating Ball Valve:

- Small and relatively inexpensive.

- Excellent ability to seal.

- Easy and quick operation.

- Minimal maintenance.

- Perfect for two-way flow.

Industries:

1)Oil and Gas Industry

2)Chemical Industry

3)Water Treatment

4)Power Generation

5)Pipelines

6)Petrochemical Industry

7)Marine Industry

Description:

Body Materials: Cast Steel (WCB,WCC,WC6,WC9),Cast Iron, SS316, SS304, F22, F51, LF2, F304, F304L, F316, F316L.

Class: 150 to 2500

Ends: Flanged, Socket weld, Butt weld, Threaded

Size:1/4’’ to 48’’

Pressure: PN 10 – PN 450

Operation: lever operated, electric actuated, pneumatic actuated, gear operated