- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

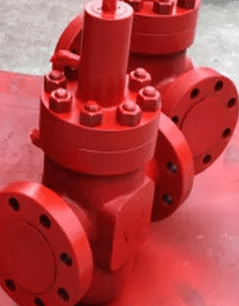

Slab Gate Valve Supplier in Doha: Efficient Sealing for Pipeline Flow Control

Middleeast Valve is the topmost Slab Gate Valve Supplier in Doha that meets the various requirements of the oil, gas, and petrochemical industries. Our slab gate valves are constructed to provide accurate flow regulation and tight sealing for stringent pipeline applications. With our durable valve solutions, customers can anticipate long-term performance in challenging applications.

Key Components:

- Body: Constructed of forged steel to withstanding high pressure

- Gate (Slab): Single solid slab with up and down movement to regulate flow

- Seats: Seals tightly on the gate to avoid leakage

- Stem: Controls the movement of the gate and comes in rising or non-rising types

- Actuator (manual or automatic): Operates the opening and closing of the valve

Working Mechanism:

Slab gate valves work by raising a solid gate between two seats to permit flow and dropping it to stop flow. Under full open conditions, the gate sits in line with the pipeline bore, thereby reducing resistance to flow. Under closed conditions, the gate is seated against the seats to create a bubble-tight seal, which is important in isolating portions of the pipeline.

Advantages:

- Full-bore design eliminates pressure drop

- Bubble-tight sealing for leak-free operation

- Low maintenance and simple to use

- Resistant to contaminants in pipelines

- Ideal for pigging operations

Functions:

The major function of a slab gate valve is to block the flow in a pipeline. It’s also utilized to safeguard downstream equipment, control pressure, and provide access for maintenance activities by safely closing off portions of the system.

Industries:

- Oil and Gas Transmission

- Petrochemical Facilities

- Pipeline Infrastructure

- Refineries

- Storage Facilities