- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

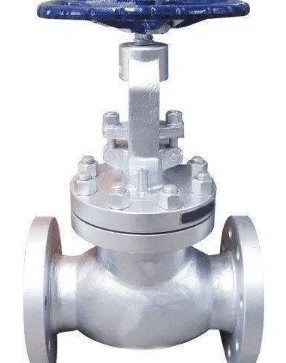

Titanium Globe Valve

Middleeast Valve is the leading manufacturer of Titanium Globe Valve that can perform even in the toughest environments. This valve is a must in cases where corrosive media, harsh temperature and high pressure are a normal threat. With their incomparable strength and resistance qualities, Titanium Globe Valve are the ideal solution for long-lasting, dependable performance.

Definition

A Titanium Globe Valve is a linear motion valve that is employed mainly for controlling flow in pipelines. Its structure consist of the spherical body and a movable disk that seat against a fixed ring, enabling the fluid movement to be controlled precisely. The employment of titanium makes the valve stronger and more corrosion resistant, ideal for aggressive chemical or marine application.

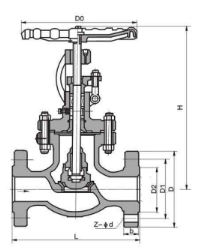

Key Components

- Valve Body: Constructed of titanium to withstand corrosion

- Bonnet: Encloses and supports the internal parts

- Stem: Attaches the handwheel to the disc

- Disc: Travels up or down to control flow

- Seat Ring: Creates a seal against the disc to throttle or stop flow

Working Mechanism

When the handwheel is rotated, the stem translates vertically, elevating or depressing the disc. This movement regulates the flow of fluid with high accuracy. Both throttling and shut-off capabilities are featured by the design of the valve, thus allowing it to be used for a variety of applications.

Advantages

- Superior corrosion resistance

- High strength-to-weight ratio

- Very good performance in high-pressure, high-temperature applications

- Longer life with low maintenance needs

Industries Served

Titanium Globe Valves find extensive usage in:

- Chemical Processing

- Marine and Offshore

- Oil & Gas

- Aerospace

- Desalination Plants

Why Is It Necessary?

Standard material tend to corrode or deteriorate in extremely aggressive or corrosive condition. Titanium Globe Valve are necessary in such situations to provide safety, efficiency and reduced downtime.

Why Purchase From Us?

We, at Middleeast Valve, are committed to quality, reliability, and customer satisfaction. Our Titanium Globe Valves are engineered with precision using top-quality titanium, tested extensively, and shipped fully in accordance with international standards. Our technical staff offers customized solutions to suit your project’s precise needs, with immediate support and worldwide shipping.