Power Generation Industry

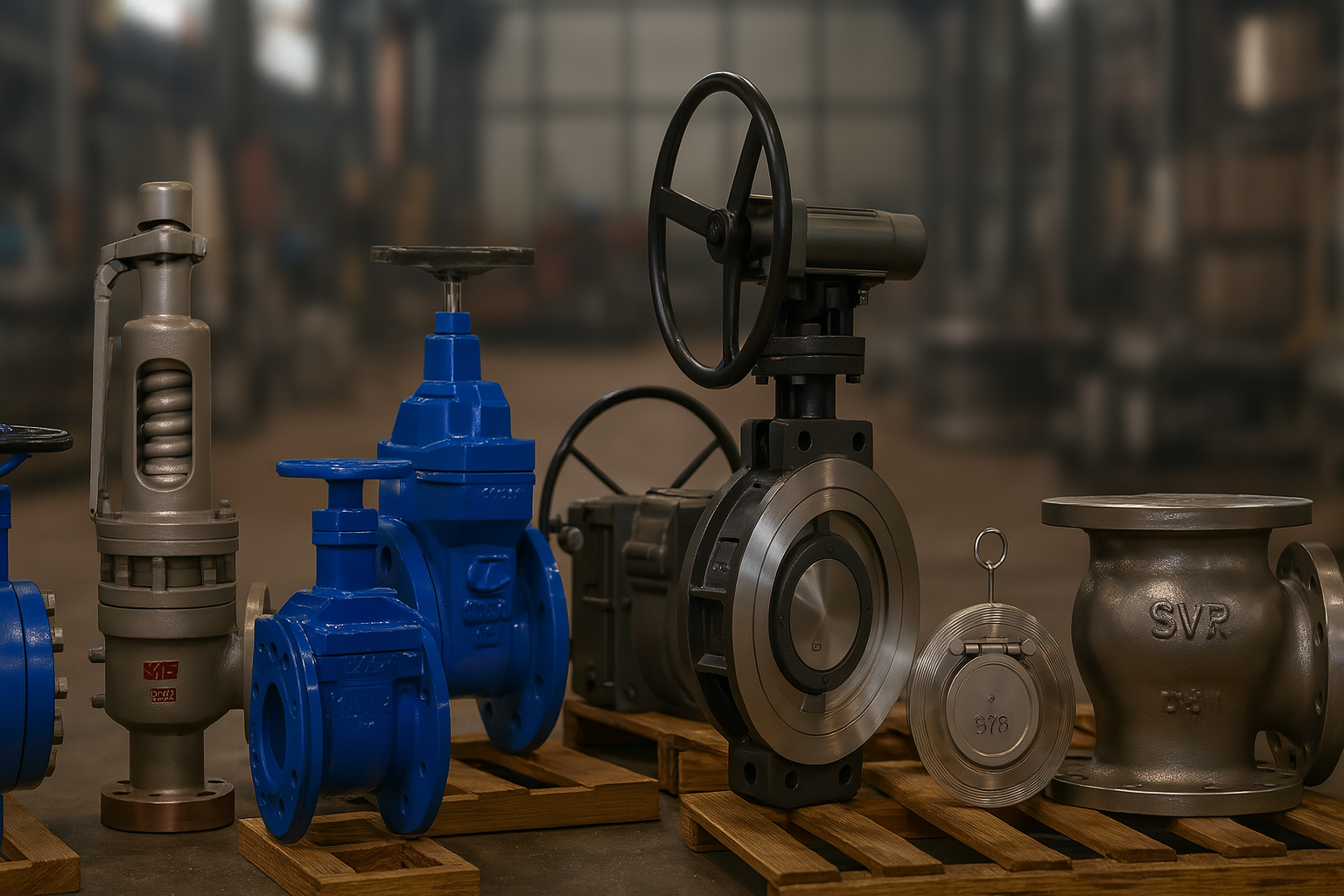

Middle East Valve delivers precision-engineered valves that meet the complex requirements of modern power plants — including thermal, hydro, nuclear, and renewable energy facilities. Our valves ensure dependable operation under extreme pressure, temperature, and flow conditions, making them ideal for steam, feedwater, condensate, and cooling circuits.

Valve Solutions Offered:

- Globe Control Valves – For precise modulation of steam and feedwater flow

- Gate Valves – Pressure-seal and bolted bonnet designs for high-pressure isolation

- Lift & Swing Check Valves – Prevent reverse flow in high-velocity lines

- Butterfly Valves – High-performance options for cooling water and air systems

- Ball Valves – Metal-seated options for turbine and boiler blowdown applications

- Safety & Pressure Relief Valves – Protect equipment from overpressure events

- Strainers & Steam Traps – Support systems for clean and efficient operation

Key Benefits:

- Designed for high-temperature, high-pressure environments (up to Class 2500)

- API, ASME, and DIN standard compliant

- Actuator integration with pneumatic, electric, or hydraulic controls

- Customizable for critical boiler and turbine systems

Application Areas:

- Boiler feedwater and superheated steam lines

- Turbine isolation and bypass systems

- Condensate recovery and deaeration units

- Ash slurry and flue gas desulfurization (FGD)

- Cooling water systems and closed-loop circuits

- Biomass, gas-fired, coal, hydroelectric, and solar thermal plants