Pulp & Paper Industry

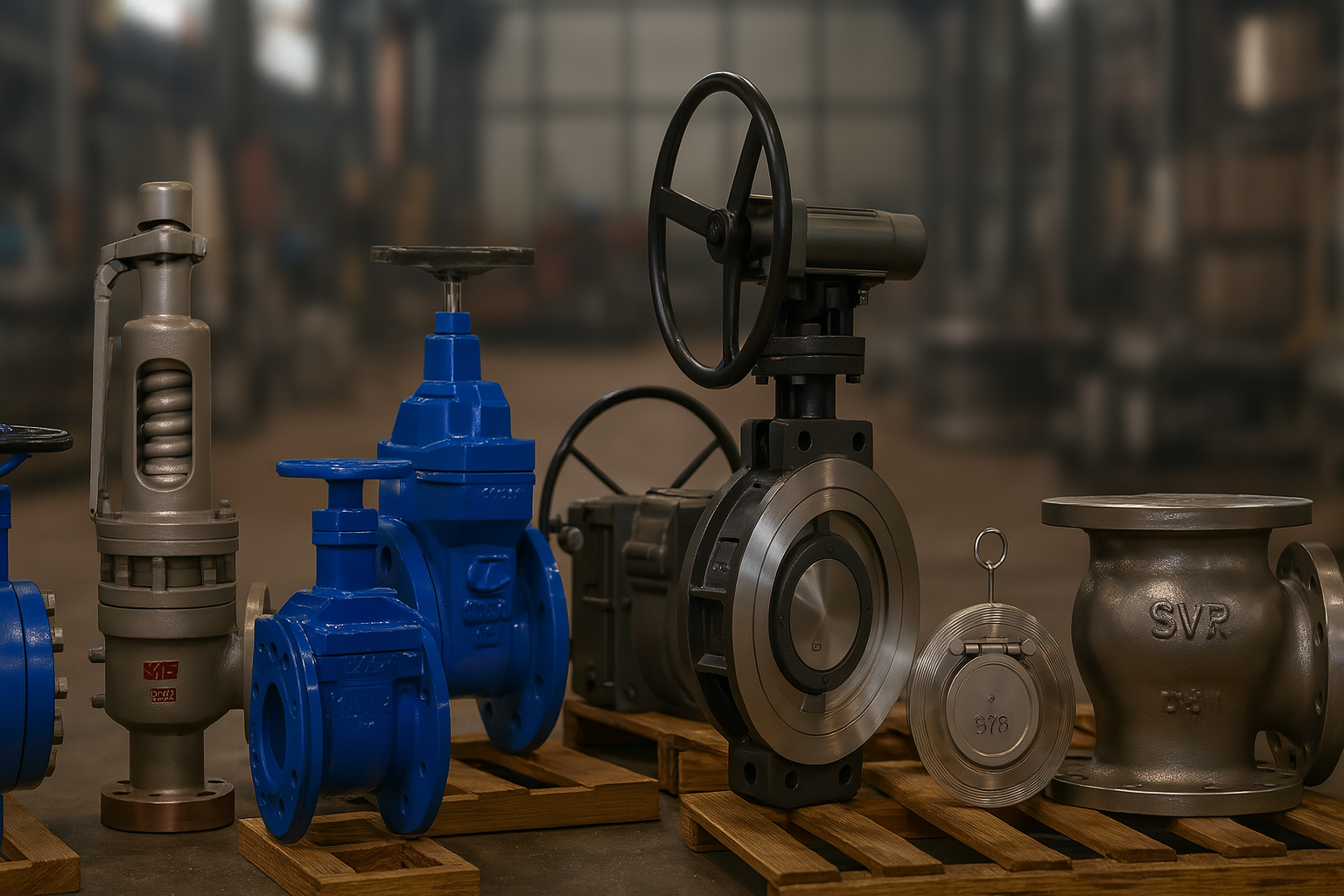

Pulp and paper mills operate under tough conditions with abrasive slurries, corrosive chemicals, and high-temperature steam. Middle East Valve supplies durable and efficient valve solutions engineered to handle fibrous materials, scaling media, and variable flow—ensuring reliable operation in stock prep, bleaching, drying, and wastewater units.

Valve Solutions Offered:

- Knife Gate Valves – For thick slurry, pulp stock, and high solids content

- High-Performance Butterfly Valves – Lightweight, reliable shut-off and control

- Ball Valves – Ideal for chemical dosing and liquor lines

- Globe Valves – Suitable for precise steam and condensate control

- Plug Valves – For lime mud and abrasive slurry applications

- Check Valves – Prevent backflow in process and utility lines

- Steam Traps & Strainers – Ensure clean, efficient steam systems

Key Benefits:

- Designed for clog-free operation with fibrous slurry

- Hard-faced trims and wear-resistant coatings available

- Materials suited for corrosive bleaching agents and black liquor

- Easy-to-maintain designs for reduced downtime

- Optional pneumatic, electric, and hydraulic actuation

Application Areas:

- Pulp stock and thickener discharge lines

- Steam, condensate, and water systems

- Bleaching and chemical recovery units

- Liquor transfer and lime kiln lines

- Wastewater treatment in paper mills

- Coating and calendaring sections