Blog

Aramco Approved Gate, Globe, Ball & Check Valves

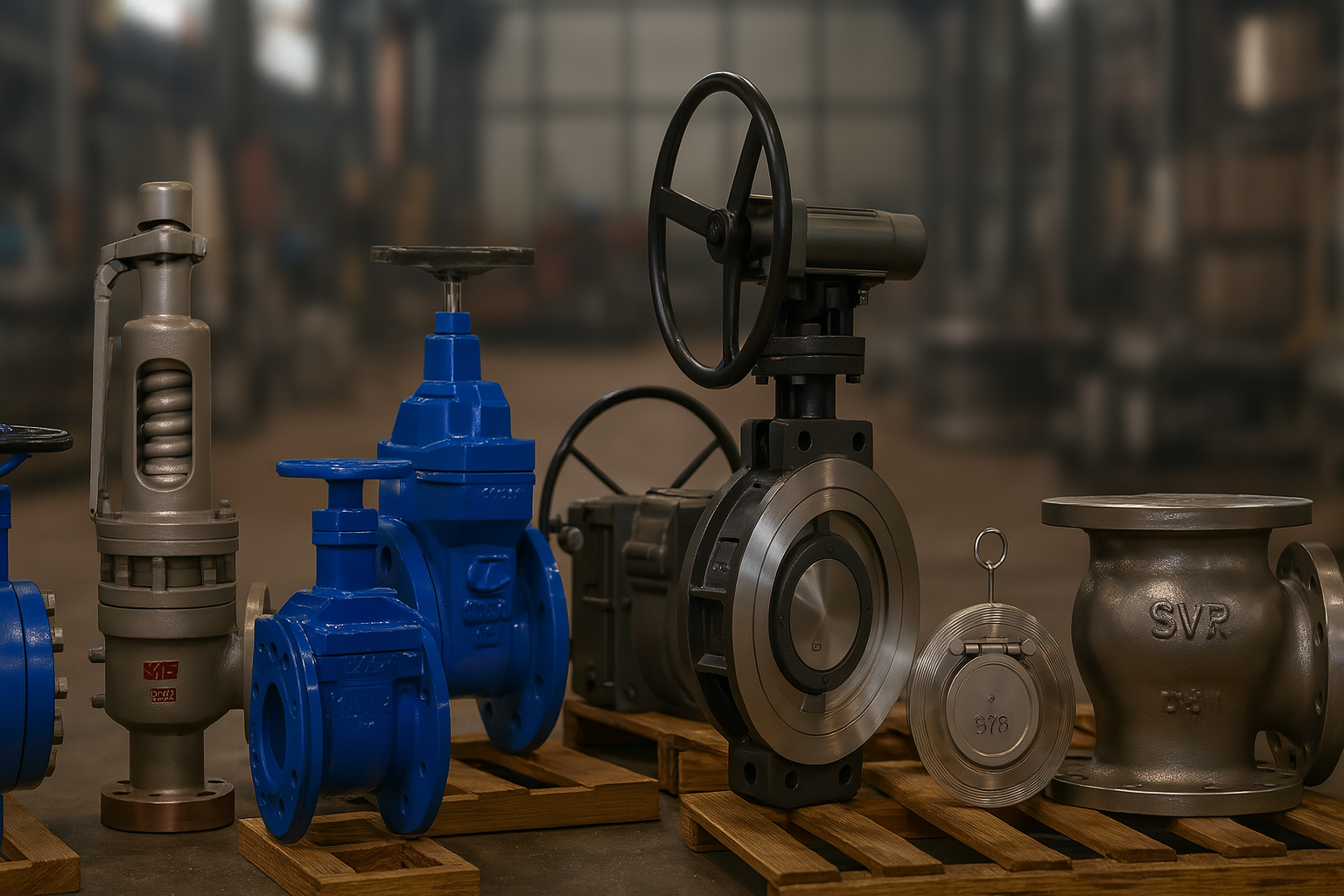

Aramco Approved Valves play a vital role in industrial operations where safety, durability, and compliance are top priorities. These valves are engineered to meet the strict standards set by Saudi Aramco, one of the world’s largest energy companies. From oil and gas facilities to water treatment and power plants, Aramco-approved valves ensure reliable performance, long service life, and operational efficiency.

This blog explores the complete product range—Gate, Globe, Ball, and Check Valves—highlighting their design, functions, and applications across critical industries.

Aramco Approved Gate Valve

Gate valves are one of the most widely used valve types in pipeline systems. Designed for on-off services, they provide tight shut-off with minimal pressure loss.

Key Features of Aramco Approved Gate Valves:

- Sizes available from ½” to 48”

- Pressure class ratings up to ANSI 2500 / PN 420

- Available in cast steel, forged steel, stainless steel, and duplex alloys

- End connections: flanged, butt-weld, or socket weld

Applications:

- Oil & gas pipelines for isolation duties

- Petrochemical and refinery units

- Power generation plants handling high-pressure steam

- Water distribution systems for reliable shut-off

Gate valves approved by Aramco ensure dependable sealing performance, even under high temperature and pressure conditions.

Aramco Approved Globe Valve

Globe valves are designed for precise flow regulation and throttling applications. Their design allows accurate control of fluids while maintaining robust sealing.

Why Aramco Approved Globe Valves are Essential:

- Excellent throttling capability

- Available in bolted bonnet, pressure seal, and bellow seal designs

- Manufactured according to API 623, DIN 3356, and ASME B16.34 standards

- Testing as per API 598 and ISO 5208

Common Uses:

- Regulating steam flow in power plants

- Chemical process industries requiring precise flow control

- High-pressure oil & gas service lines

- Water treatment systems

These valves are built to maintain efficiency, reduce leakage risks, and comply with Aramco’s strict operational standards.

Aramco Approved Ball Valve

Ball valves are known for their quick operation and bubble-tight sealing. With a simple quarter-turn motion, they allow or block flow efficiently.

Features of Aramco Approved Ball Valves:

- Floating and trunnion-mounted designs

- Sizes ranging from ½” to 36”

- Fire-safe, anti-static, and blow-out proof stem design

- Soft-seated and metal-seated options

Industries Served:

- Offshore and onshore oil & gas facilities

- LNG and cryogenic applications

- Refining and petrochemical plants

- Power generation and water projects

By choosing Aramco Approved Ball Valves, industries benefit from long-lasting performance and easy maintenance, even under challenging environments.

Aramco Approved Check Valve

Check valves are essential for preventing reverse flow, protecting pumps, and avoiding damage in pipeline systems.

Types of Aramco Approved Check Valves:

- Swing check valve

- Dual plate check valve

- Tilting disc check valve

- Lift check valve

Specifications:

- Available in pressure classes up to ANSI 2500

- Materials: WCB, CF8M, duplex steel, and exotic alloys

- End connections: flanged, butt weld, socket weld, threaded

Applications:

- Oil & gas processing plants

- Power plants requiring backflow prevention

- Water distribution networks

- Marine and offshore facilities

With Aramco approval, these check valves guarantee reliability in critical backflow prevention duties.

Advantages of Aramco Approved Valve:

- Compliance with international standards: API, ASME, DIN, and Aramco specifications

- High durability: Built for corrosive, high-temperature, and high-pressure environments

- Project-ready: Suitable for large-scale oil, gas, water, and power projects

- Safety assurance: Tested and certified for leak-tight performance

Choosing the Right Aramco Approved Valve Supplier:

Selecting the right supplier ensures timely delivery, technical support, and full compliance with Aramco standards. Buyers should always verify certifications, testing documents, and approvals before procurement.