Blog

Applications of Inconel Valves in High-Temperature and High-Pressure systems

Inconel valve applications are essential for systems that operate at extremely high temperatures and pressures, conditions in which the materials of normal valves would fail. The use of such valves has been extended to various industries like oil & gas, power generation, petrochemical, and offshore because of the properties of Inconel which include maintaining strength, resistant to corrosion, and giving reliable performance when subjected to severe thermal and pressure loads.

For industries such as oil & gas, power generation, petrochemical processing, and marine systems, those that work in harsh environments have to guarantee safety, uptime, and long term reliability. As a leading manufacturer in Middle East, Middleeast Valves is providing Inconel valve solutions that are engineered to operate steadily in situations that are characterized by high risks and heavy demands.

Why Inconel is used in severe service valves

Across critical industrial sectors, inconel valves applications are primarily driven by the need for materials that can withstand extreme heat, high internal pressure, and aggressive chemical exposure without loss of mechanical integrity or sealing performance. This makes Inconel a preferred alloy for severe service valves operating where failure risks are unacceptable.

Key material properties of Inconel

- Maintains mechanical strength at temperatures exceeding 1000C

- Excellent resistance to oxidation and carburization

- High tolerance to extreme pressure and thermal cycling

- Superior resistance to chlorides, sulfides, and acidic media

- Low creep and deformation under sustained stress

These characteristics make Inconel an ideal material for valve bodies, trims, stems, and pressure, retaining components operating in harsh service conditions.

High-Temperature Applications of Inconel Valves

In upstream and downstream oil & gas facilities, valves are exposed to elevated temperatures combined with corrosive hydrocarbons, hydrogen sulfide, and high pressure.

- Heater and furnace isolation systems

- High-temperature gas handling lines

- Sour service applications

Their resistance to sulfide stress cracking and oxidation ensures stable performance where standard alloys degrade rapidly.

Power Generation Systems

Thermal and combined-cycle power plants rely on valves capable of withstanding extreme temperatures and pressure fluctuations.

Inconel Valves are widely applied in:-

- Steam control and isolation lines

- Boiler feedwater systems

- Turbine bypass and auxiliary systems

As high temperature valves, Inconel-based designs prevent creep failure and maintain tight shutoff under continuous thermal stress.

Petrochemical and Chemical Processing

Petrochemical plants handle aggressive chemicals at elevated temperatures that can cause rapid corrosion and embrittlement in conventional materials.

Inconel valves are used in:

- Reactor feed and discharge lines

- Acid gas processing units

- High-temperature chemical transfer systems

Their resistance to pitting, oxidation, and chemical attack ensures extended service life and reduced maintenance intervals.

High-Pressure Applications of Inconel Valves

High-pressure gas systems

Inconel valves perform reliably in high, pressure gas services where pressure containment and structural integrity are critical.

Typical applications include:-

- Gas compression and injection systems

- Hydrogen and synthesis gas pipelines

- High-pressure isolation and control valves

As high pressure alloy valves, Inconel designs maintain dimensional stability and sealing performance even under extreme pressure loads.

Offshore and Marine systems

Offshore platforms operate in environments combining high pressure, salt, laden atmospheres, and elevated temperatures.

Inconel valves are commonly installed in:-

- High-pressure hydrocarbon processing lines

- Seawater lift and injection systems

- Firewater and safety-critical isolation valves

Their superior resistance to chloride, induced corrosion and stress corrosion cracking makes them suitable for long, term offshore service.

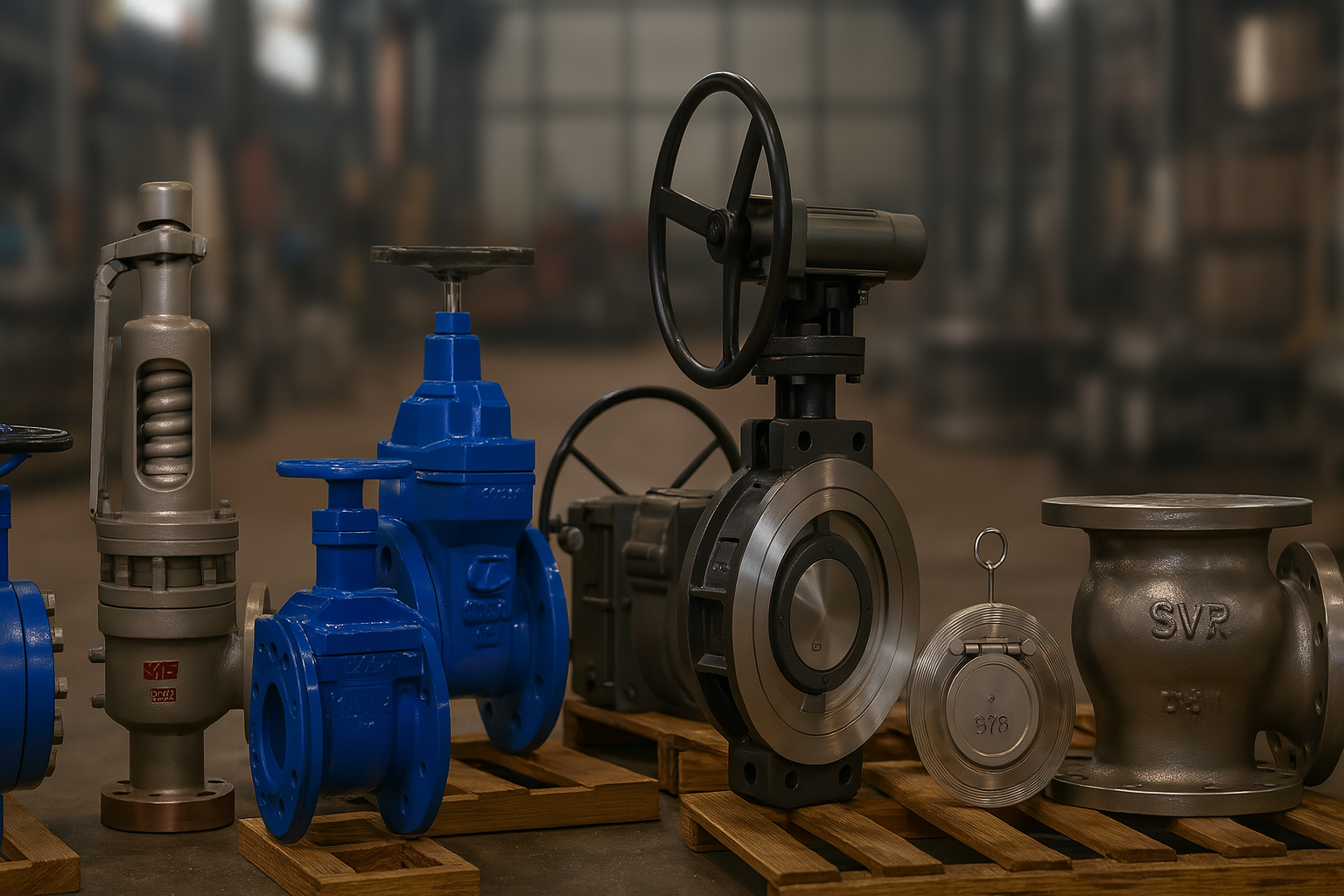

Valve Types Commonly Manufactured in Inconel

Middleeast Valves manufactures and supplies multiple valve types using Inconel alloys to meet severe service requirements:

- Gate Valves- For high-pressure and high-temperature isolation

- Globe Valves- For throttling and flow regulation under extreme conditions

- Ball Valves – For tight shut-off in high-pressure systems

- Check Valves – To prevent backflow in high-temperature pipelines

- Pressure Relief and Safety Valves- For overpressure protection in critical systems

Depending on the severity of the service, Inconel may be used for the entire valve construction or only for the trims and pressure-retaining parts.

Selection Consideration for Inconel Valves

Determining Inconel valve installation should be thoroughly assessing the working conditions rather than just material cost.

Key Points to consider:-

- Temperature range of the operation and thermal cycling

- Maximum system pressure and pressure fluctuations

- Nature of the process media (corrosive, sour, oxidizing)

- Criticality of service and safety classification

- Accessibility for maintenance and expected service life

Inconel valves are a safer operational alternative in systems where failure may cause harm to people, loss of production, or pollution of the environment.

Cost Vs Performance Perspective

The life cycle cost of an Inconel valve is substantially lower compared to stainless steel or low-alloy alternatives, although it comes with a higher initial investment. Reduced downtime, less maintenance, and longer service life, which are often true for high-risk applications, are the factors that pay off the initial cost. When it comes to high- temperature valves and high- pressure alloy valves, Inconel is still one of the most dependable materials available.

Inconel valves are essential components in high-temperature and high-pressure systems that are beyond the capability of standard materials. The combination of Inconel valves to resist overheating, overpressure, and corrosive environments, has made them a necessity in oil & gas, power generation, petrochemical, and offshore industries.

As a leading manufacturer in Middle East, Middleeast Valves offers custom Inconel valve solutions for tough service situations that result in safety, durability, and long-term operational reliability even in extreme conditions.