Blog

ARAMCO Valve Standards Explained: API, ASME & Material Requirements

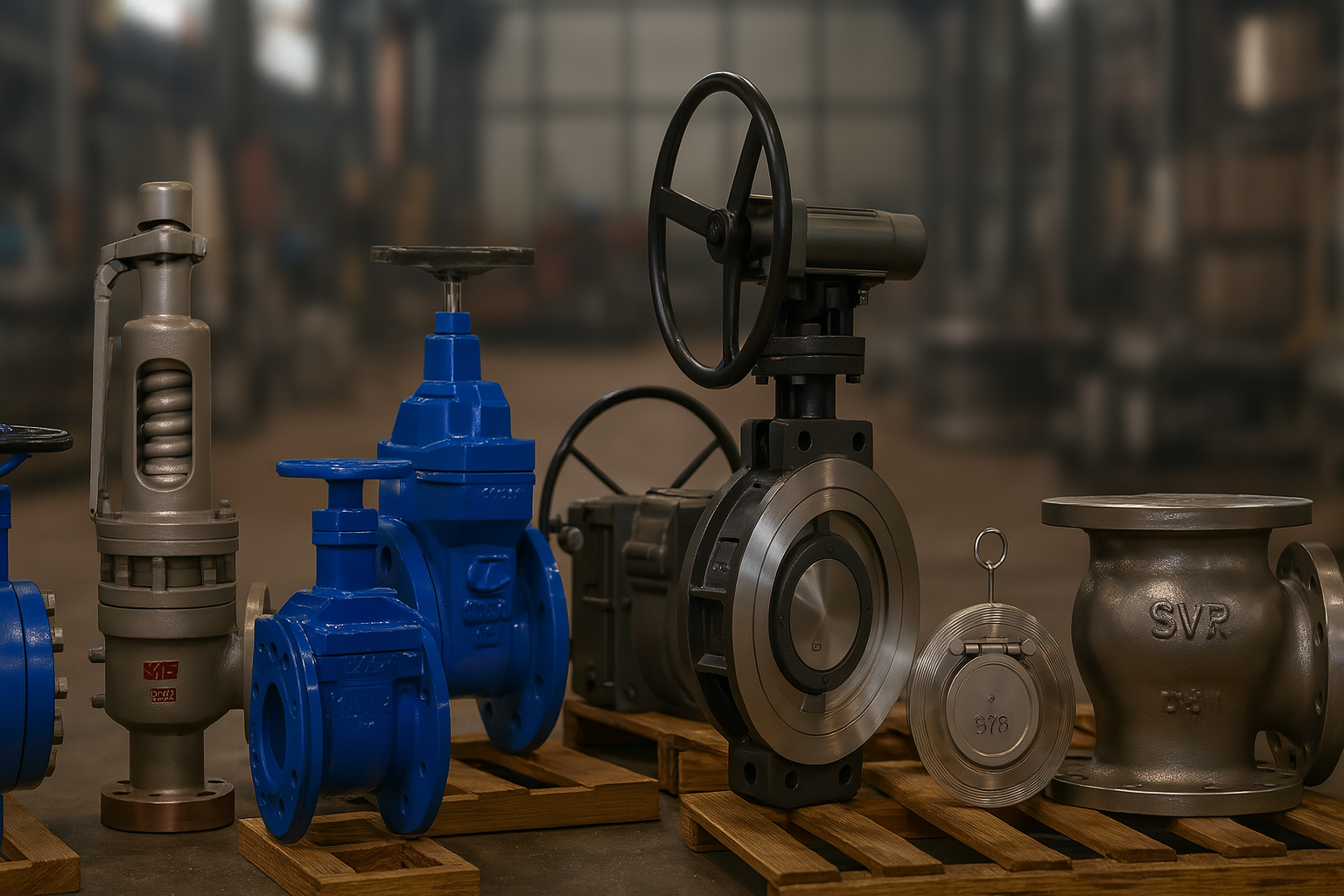

ARAMCO valves standards are one of the most technical and highest in terms of their quality in the international petroleum sector. Apart from meeting the internationally recognized API and ASME standards, ARAMCO valves are also required to meet the company’s own engineering requirements.

It is essential for the EPC Contractors, project owners, as well as the procurement teams to have a good understanding of the above requirements in order to prevent any delay in approvals, disapprovals, as well as rework. The article will show how the ARAMCO valve approval, API, as well as the ASME specifications, are applied in order to fulfill the requirements for the procurement of the ARAMCO approved valves.

What ARAMCO Valve Approval Means for Oil & Gas Projects?

Aramco valve approval goes beyond basic compliance with API or ASME standards. A valve may be API-certified and still be rejected if it does not meet Aramco’s additional requirements related to material traceability, inspection procedures, or quality documentation.

For oil & gas projects, Aramco approval ensures that:

- Valves are suitable for long-term operation under severe service conditions

- Materials meet sour service, corrosion, and temperature requirements

- Manufacturing, testing, and inspection follow controlled and auditable processes

- Only manufacturers and suppliers that demonstrate consistent compliance are accepted for Aramco projects.

Why ARAMCO Valve Standards Are Stricter Than Standard API Compliance

API standards set the minimum requirements for the industry. Nevertheless, a stricter code is applied by Saudi Aramco to minimize the danger throughout their upstream, midstream, as well as downstream assets

Key differences include:-

- Stricter material acceptance criteria

- Mandatory compliance with NACE requirements for sour service

- Enhanced testing and inspection scope

- Extensive documentation review and approval

As a result, API valves Saudi Arabia projects often require additional verification beyond standard API certification.

Role of API and ASME Standards in ARAMCO Valve Approval

How API Standards Define Valve Design and Performance

API standards form the foundation of valve design, manufacturing, and testing. They establish requirements for:

- Pressure containment and sealing performance

- Operational torque and cycle life

- Inspection, testing, and acceptance criteria

Nevertheless, API compliance, in general, is not enough for acceptance by Aramco.

How ASME codes control Pressure Ratings and Materials?

ASME standards are used to relate the pressure/temperature limits, the dimensions of the flange, and the strength of the material for valves that are going to be used in Aramco facilities. These standards are there to make sure that the valves can be safely used under the specified pressure classes and temperature ranges. Together, API and ASME valve standards provide the technical baseline that Aramco builds upon.

Key API Valve Standards Referenced by ARAMCO

Saudi Aramco often uses the following API standards as reference in the specs of the project:

- API 600: This specification is related to steel gate valves that are used in refinery operations, pipelines, and isolation duties.

- API 602: Specified use with high pressure and high-temperature application forged steel valves.

- API 6D: Specifies requirements for pipeline ball and plug valves for transmission and distribution pipelines.

- API 598: Outlines inspection and pressure test procedures for production valves

- API 526: Covers safety and pressure relief valves where applicable in overpressure protection systems.

Each of these standards is typically supplemented by Aramco-specific material and testing requirements.

ASME Standards Applicable to ARAMCO Valve Projects

- ASME B16.34: Establishes the pressure-temperature ratings and materials for construction of valves

- ASME B16.5, ASME B16.47: Contain information regarding flange dimensions, facing types and pressure classes

- ASME Section IX: Covers the procedures followed during welding activities; records for welder qualifications.

- ASME Boiler & Pressure Vessel Code – Section VIII: The design standard for pressure-containing

- ASME Section VIII: The design standard for pressure-containing components

Compliance with these standards is mandatory for ARAMCO approved valves used in pressure systems.

ARAMCO Valve Materials Requirements:

Material selection is a very important part of Aramco approval, especially for sour, high pressure and corrosive services.

| Material Category | Common Grades | Typical Applications | Key Considerations |

| Carbon Steel | ASTM A216 WCB, ASTM A105 | Non-corrosive hydrocarbon service, moderate temperature and pressure systems | Cost-effective; not suitable for sour or high-corrosion environments |

| Stainless Steel | CF8, CF8M | Corrosive process fluids, refinery units, chemical handling | Improved corrosion resistance; hardness control required for sour service |

| Duplex Stainless Steel | Duplex grades (as specified by project) | Sour service, offshore and coastal installations, chloride-rich environments | High strength and resistance to pitting and stress corrosion cracking |

| Super Duplex Stainless Steel | Super duplex grades (project-specific) | Severe offshore and high-chloride service | Enhanced corrosion resistance and mechanical strength |

| Alloy Steel / Nickel Alloys | Project-specified alloy grades | High-temperature, high-pressure, and highly corrosive services | Selected based on temperature limits, chemical compatibility, and pressure rating |

Testing, Inspection, and Certification for ARAMCO Valves

Saudi Aramco imposes very strict testing and documentation requirements. Such as:-

Pressure Testing

- Hydrostatic and shell testing as per API 598

- Seat leakage testing based on valve type

Sour Service Compliance

- Mandatory NACE MR0175 / ISO 15156 compliance

- Verification of hardness limits and material chemistry

Fire-Safe Testing

- API 607 or API 6FA fire-safe certification where applicable

Documentation Requirements

- Material Test Certificates (MTC)

- Quality Assurance Plan (QAP)

- Inspection and Test Plan (ITP)

- Third-party inspection reports

Common Compliance Issues in ARAMCO Valve Supply

Despite API certification, valves are often rejected due to:

- Missing Aramco-specific documentation

- Incorrect or untraceable material heat numbers

- Incomplete inspection or test reports

- Non-approved material substitutions

These issues can delay project schedules significantly.

How EPC Contractors Evaluate ARAMCO Approved Valve Suppliers

EPC contractors assess suppliers based on more than product specifications.

Key evaluation criteria include:

- Proven Aramco approval history

- Manufacturing capability and quality systems

- Compliance with API and ASME standards

- Past project references within Saudi Arabia

- Incomplete documentation is a common reason for rejection.

- Suppliers without proven experience are at higher risks of disapproval

Choosing ARAMCO-Compliant Valves for Saudi Arabia Projects

In order to avoid procurement difficulties, buyers should:

- Match valve material and type to operating circumstances.

- Verify applicable API and ASME standards early

- Confirm sour service and fire-safe requirements

- Ensure full documentation availability before ordering

- Early technical alignment lowers approval delays and rework.

Successful valve purchase in Saudi oil and gas projects depends on knowledge of ARAMCO valve standards. Rigid adherence to API and ASME standards, controlled material selection, extensive testing, and thorough documentation are all requirements for Aramco authorization. The selection of a proper supplier of ARAMCO-approved valves is important and ensures conformance, reduces risks and assures stable operation. Regarding projects in Saudi Arabia, matching valve selection with Aramco requirements from the outset is important within a project to ensure specified criteria in performances, quality, and specifications.