Blog

Different Types of Valves Used in Water Pipelines

Water pipeline systems are a critical part of industrial, and utility infrastructure. Whether pipelines are transporting potable water, cooling water, or process water, uninterrupted operation, safety, and efficiency are essential. In these systems, water pipeline valves play a central role in controlling flow, managing pressure, and protecting the network from operational failures.

As a leading manufacturer in the Middle East, Middleeast Valves supplies a wide range of robust valves that ensure precise flow control, pressure management, and system protection in diverse water pipeline applications. This article elaborates on the types of valves used in water pipelines and also explains why valves are necessary in water distribution systems.

Why Valves Are Needed in Water Pipelines

Valves are not merely accessories in pipeline systems; they are critical control elements. Their importance can be understood through the following core functions:

- Flow Control and Regulation

Valves are the devices that enable operators to start, stop or regulate water flow in accordance with system demand. In the absence of valves, pipelines would function incessantly making it impossible to carry out maintenance, flow adjustment, or emergency shutdowns.

- System Isolation and Maintenance

Isolation valves make it possible to shut off a specific section of a pipeline without stopping the whole network. They are very important during repair, upgrade, or inspection and minimize the time of stoppage and losses of water.

- Pressure Management and Safety

Overpressure can damage pipes, fittings, and equipment. Hence, pressure control and relief valves are there to protect the system by regulating pressure levels and preventing situations such as pipe bursts that could be disastrous.

- Backflow Prevention

Backflow can pollute clean water sources and lead to the deterioration of pumping equipment. Check valves accomplish this by ensuring flow in one direction only, thus they are the devices that preserve water quality and the integrity of the system.

- Operational Efficiency and Cost Reduction

Valve proper selection enhances hydraulic efficiency, decreases leakage, lowers maintenance costs, and increases the overall lifespan of pipeline systems.

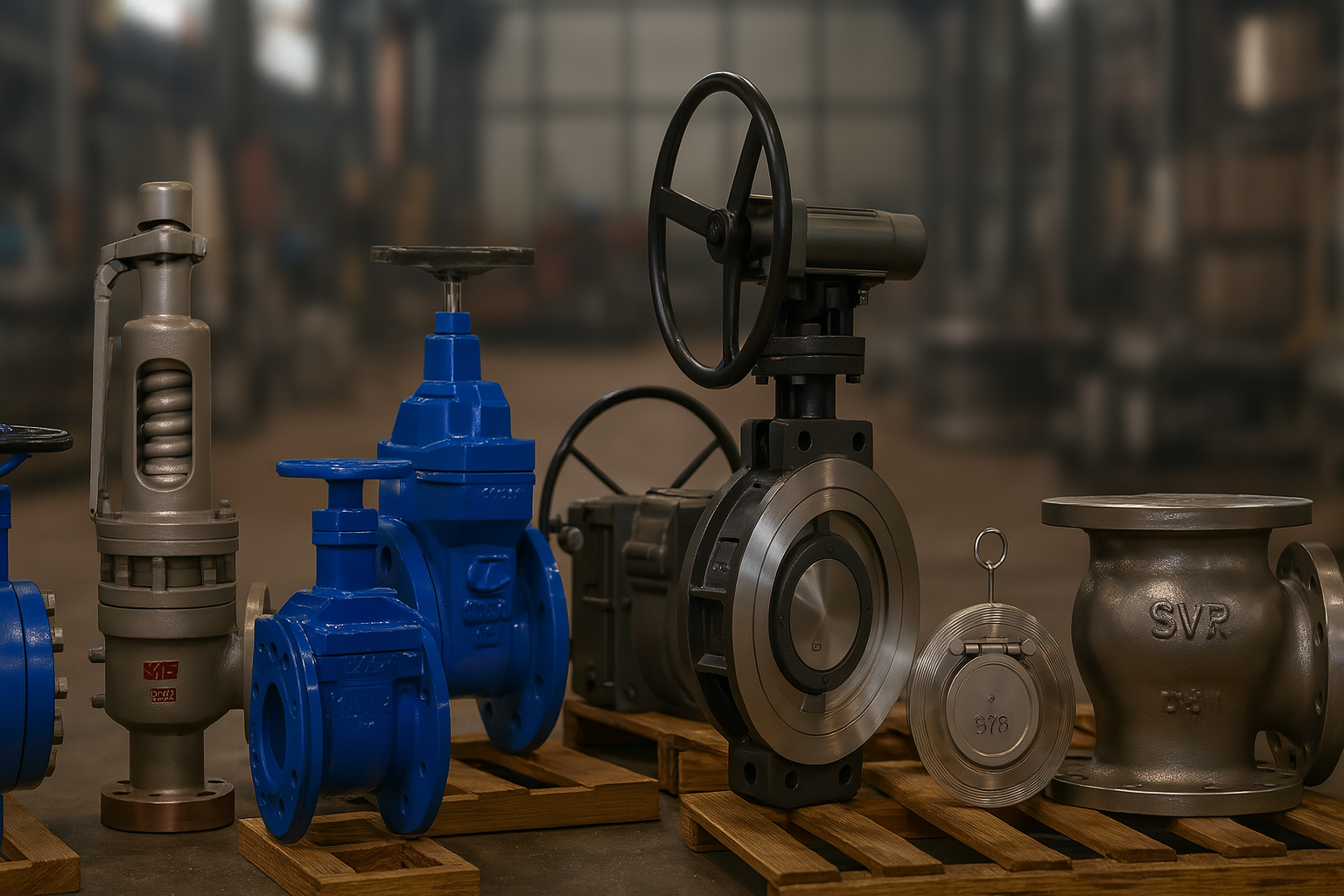

Types of Valves used in Water Pipelines

- Ball Valves

Ball valves function by using a hollow, perforated sphere that rotates inside the valve body to regulate the flow.

Advantages:

- Quick quarter-turn operation

- Excellent sealing and minimal leakage

- Clear visual indication of open or closed position

Applications:-

Residential plumbing, industrial water lines, emergency shutoff systems

- Butterfly Valves

Butterfly valves consist of a rotating disc fixed on a shaft that is used to regulate the flow.

Advantages:-

- Lightweight and compact

- Cost-effective for large diameter pipelines

- Low installation space required

Applications:-

Municipal water networks, HVAC systems, fire protection pipelines

- Check Valves

Check valves permit flow in one direction and do not require the intervention of an operator to close automatically.

Advantages:

- Automatic operation without external control

- Protects pumps and upstream equipment

- Low maintenance

Applications:-

Pumping stations, Water treatment plants, irrigation systems

- Gate Valves

Gate valves direct the flow by raising or lowering an internal gate or wedge.

Advantages:

- Minimal pressure drop when fully open

- Suitable for full open or full close operation

- Durable for long-term service

Applications:

Main water supply lines, municipal pipelines, older residential systems

- Globe Valves

Globe valves operate by using a movable disc which is controlled by a stem to regulate flow.

Advantages:

- Precise throttling capability

- Reliable shut-off

- Easy maintenance

Applications:

Boiler feedwater systems, cooling water circuits, industrial utilities

- Pressure Relief Valves

Pressure relief valves are fitted in a system to automatically vent the excess pressure to safety.

Advantages:

- Prevents pipeline and equipment damage

- Enhances system safety

- Necessary for high-pressure applications

Applications:-

Residential water systems, industrial pipelines, pressure sensitive installations

- Plug Valves

Plug valves make use of a cylindrical or conical plug with a through-hole to regulate the flow.

Advantages:

- Quick operation

- Tight shut-off

- Fluids with suspended solids

Applications:-

Industrial water pipelines, utility services, process water systems

- Needle Valves

Needle valves provide fine control over low flow rates using a needle-shaped plunger.

Advantages:

- High precision

- Ideal for metering applications

- Stable flow control

Applications:

Instrumentation lines, pressure monitoring systems, calibration setups

How to Select the Right Valve for Water Pipelines

Valve selection depends on operating conditions, system design, and performance requirements:

- For on/off isolation: Ball valves or gate valves

- For flow regulation: Globe valves or butterfly valves

- For large-diameter pipelines: Butterfly valves

- For backflow prevention: Check valves

- For pressure protection: Pressure relief valves

- For precision flow control: Needle valves

Choosing the right valve ensures long-term reliability, safety, and cost-effective operation of water pipeline systems.

Valves play a crucial role in the operation of water pipeline systems that are safe, efficient, and under control. With the help of valves, it is possible to regulate flow, isolate the system, control pressure, and prevent backflow, which are the main functions that serve the protection of the infrastructure and uninterrupted water supply. Knowing the functions for which valves are necessary and what valve type is the most suitable for the particular application lead to the creation of water distribution networks that can be trusted.

As a leading manufacturer in Middle East, Middleeast Valves is offering engineered valve solutions that comply with global quality standards and are capable of meeting the ever changing requirements of the water infrastructure of the future.