- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Description

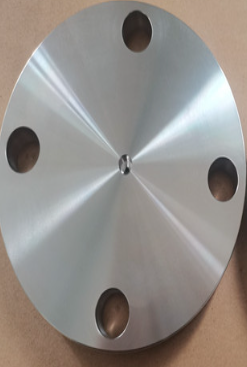

Blind Flange Supplier in Kuwait: Leak-Tight End Connection for Piping Systems

Middleeast Valve is the trusted manufacturer and supplier of high-quality industrial valves and fittings, including the reliable Blind Flange – Middle East Valve known for durability and performance across demanding industrial sector.

Why is it used?

Blind flanges are usually used for blocking pipes and closing path. These flanges will completely stop the flow of the material running through the passage. They are ideal for blocking pipes in the piping system, valve, and pressurized containers.

Components:

Blind flanges are made of sturdy material such as carbon steel, stainless steel or alloy steel, depending on the pressure and temperature of the pipeline. Key components include the solid plate body, gasket surface, and bolt holes arranged in a circular pattern.

Working Mechanism:

A blind flange is bolted between two pipe flanges and sealed using a gasket. When installed, it effectively seals the end of a pipe, halting flow. This makes it essential in testing flow systems and isolating parts of the piping during shutdown or modification. Its pressure-bearing capacity matches that of standard flanges.

Applications

- Oil and gas

- Petrochemical

- Water treatment

- Power generation industries