Blog

SWCC Approved Valve Supplier in Saudi Arabia

As an SWCC approved valve supplier Saudi Arabia, we provide engineered industrial valve solutions specifically designed for Saline Water Conversion Corporation (SWCC) desalination and water transmission projects across KSA.

We support desalination and water infrastructure projects across Riyadh, Jeddah, Jubail, Yanbu, Ras Al Khair, Dammam, and other key SWCC operational regions in Saudi Arabia.

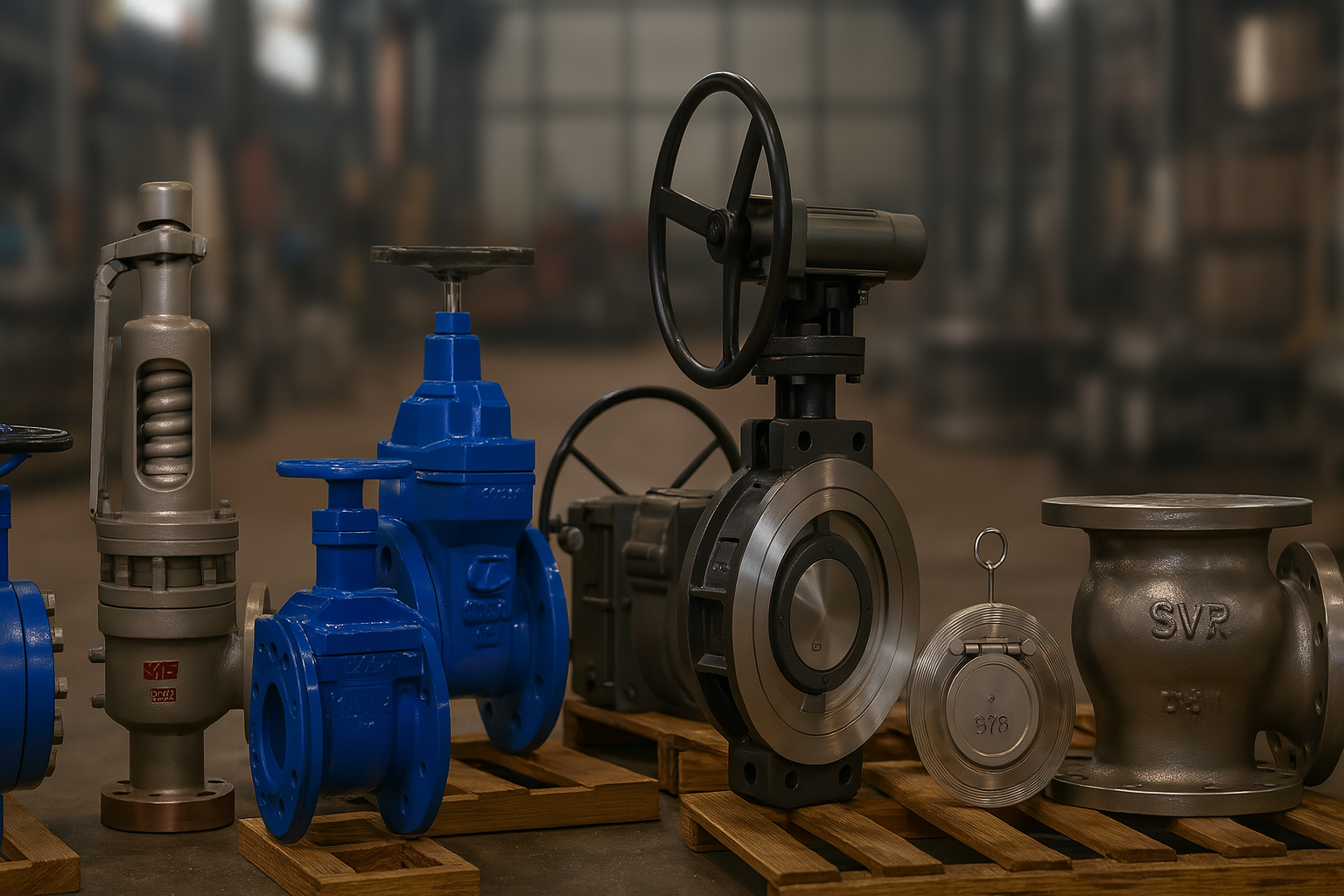

SWCC projects in Saudi Arabia require engineered industrial valves designed for high salinity, high pressure, and continuous desalination plant operation. Reliable valve performance is critical across seawater intake, reverse osmosis systems, transmission pipelines, and automated treatment facilities.

We are a trusted SWCC desalination valve supplier. We provide corrosion-resistant, high-performance valve solutions for seawater intake, RO high-pressure systems, transmission pipelines, and automated treatment facilities across KSA.

Why SWCC Projects Require Specialized Valve Suppliers

- High chloride and saline exposure

- Continuous 24/7 plant operation

- Strict material traceability

- Hydrostatic & performance testing compliance

- Project documentation & inspection approval

As a trusted Valve supplier for SWCC projects, we guarantee that all industrial valves adhere to the stringent standards for high salinity, high pressure, and continuous desalination plant operation

Seawater Intake

Seawater intake applications require materials capable of maintaining structural integrity while resisting biofouling, erosion, and chloride-induced corrosion.

Aluminium bronze and other seawater-resistant materials are selected to ensure dependable flow control and extended service life in harsh marine environments. Proper valve specification at the intake stage protects downstream equipment, maintains hydraulic efficiency, and reduces the impact of saline exposure on system components.

RO High-Pressure Systems

Reverse osmosis systems operate under extreme pressure conditions that demand high strength materials and reliable sealing performance.

Duplex and super duplex stainless steel valves provide resistance to chloride stress corrosion cracking and maintain structural stability under fluctuating pressure loads. These materials ensure membrane efficiency, reduce pressure losses, and ensure consistent treatment performance across high-pressure process skids.

Large Diameter Transmission Lines

Large transmission pipelines require valves capable of handling high flow volumes while maintaining dependable sealing performance.

PN16 and PN25 butterfly valve solutions support efficient distribution across large diameter lines. Their design ensures low operating torque, reliable shut-off capability, and reduced operational strain on pumping equipment. We are also a SWCC water transmission valve supplier, ensuring dependable operation throughout important pipelines in every SWCC area.

Pump Discharge Protection

Pump discharge systems require protection against reverse flow and hydraulic shock to prevent equipment damage and operational instability.

Check valves and non-return valves prevent backflow, stabilize pressure conditions, and protect pumps and downstream infrastructure maintaining stable system operation in desalination facilities. Effective backflow control contributes to improved system reliability and extended equipment lifespan.

Isolation Control

Isolation valves play a critical role in ensuring safe maintenance, and controlled system shutdown.

Gate valves and resilient seated isolation valves ensure safe maintenance and dependable shut-off performance under varying operating conditions. Proper isolation capability supports operational continuity while allowing safe inspection and servicing procedures.

Automation & Actuation

Modern desalination facilities rely on automated control systems to maintain process accuracy and operational stability.

Actuated and motorized valve solutions support automated control systems and integrate with plant control systems to improve process stability, improve response time, enhance flow regulation accuracy, and reduce manual intervention across treatment systems.

Anti-Corrosion Engineering

Desalination environments expose valves to chloride-rich water, chemical treatment agents, and continuous moisture.

Advanced alloys and protective coating systems are used to resist pitting, crevice corrosion, and chemical attack in chloride-rich environments. Careful material selection extends service life, reduces maintenance frequency, and preserves consistent valve performance in aggressive operating conditions.

Compliance & Documentation

Valve solutions are supplied in alignment with SWCC project specifications and applicable international standards, including testing documentation, quality assurance procedures, and traceability records to support project compliance.

Comprehensive documentation packages include material traceability records, hydrostatic and performance testing reports, inspection certificates, and quality assurance documentation. Adherence to specification requirements ensures regulatory compliance, operational safety, and long-term system integrity.

Conclusion

Selecting the right industrial valves is essential for ensuring efficient desalination operations across seawater intake, treatment, distribution systems and transmission systems.

By focusing on material performance, corrosion resistance, automation and compliance, engineered valve solutions support long-term operational stability and reliable performance across SWCC desalination projects in Saudi Arabia