Blog

Valves Used in Saudi Arabia’s Oil and Gas Industry: Types, Standards & Applications

Saudi Arabia has long stood as a global powerhouse in the oil and gas industry. From the heart of the Eastern Province to offshore platforms in the Arabian Gulf, the Kingdom’s energy sector relies on advanced infrastructure—and industrial valves are a vital part of that. These unsung components play a critical role in flow control, safety, and system reliability.

With the significant growth in the oil and gas sector, understanding the various components, such as valves, becomes even more crucial.

The oil and gas industry in Saudi Arabia is a key player in the global market.

In oil and gas operations, valves play a crucial role in ensuring safety and efficiency.

In this blog, we will explore the types of valves commonly used in Saudi Arabia’s oil & gas sector, the standards that guide their design, and their key applications across upstream, midstream, and downstream processes.

These valves are critical for the efficient transport of oil and gas resources.

Valves are vital for sustaining operations in the oil and gas industry.

Understanding the standards in the oil and gas sector is vital for operational success.

Why Valves Matter in Oil and Gas Operations

Valves are essential in managing the flow of crude oil, natural gas, and associated by-products. Whether it’s controlling pressure in a pipeline or shutting off flow during an emergency, each valve must operate under extreme conditions such as high pressure, corrosive media, and elevated temperatures. Reliability is non-negotiable.

Saudi oil fields like Ghawar, Safaniya, and Khurais demand high-performance valve systems, approved by globally recognized standards—and more importantly, by local entities like Saudi Aramco.

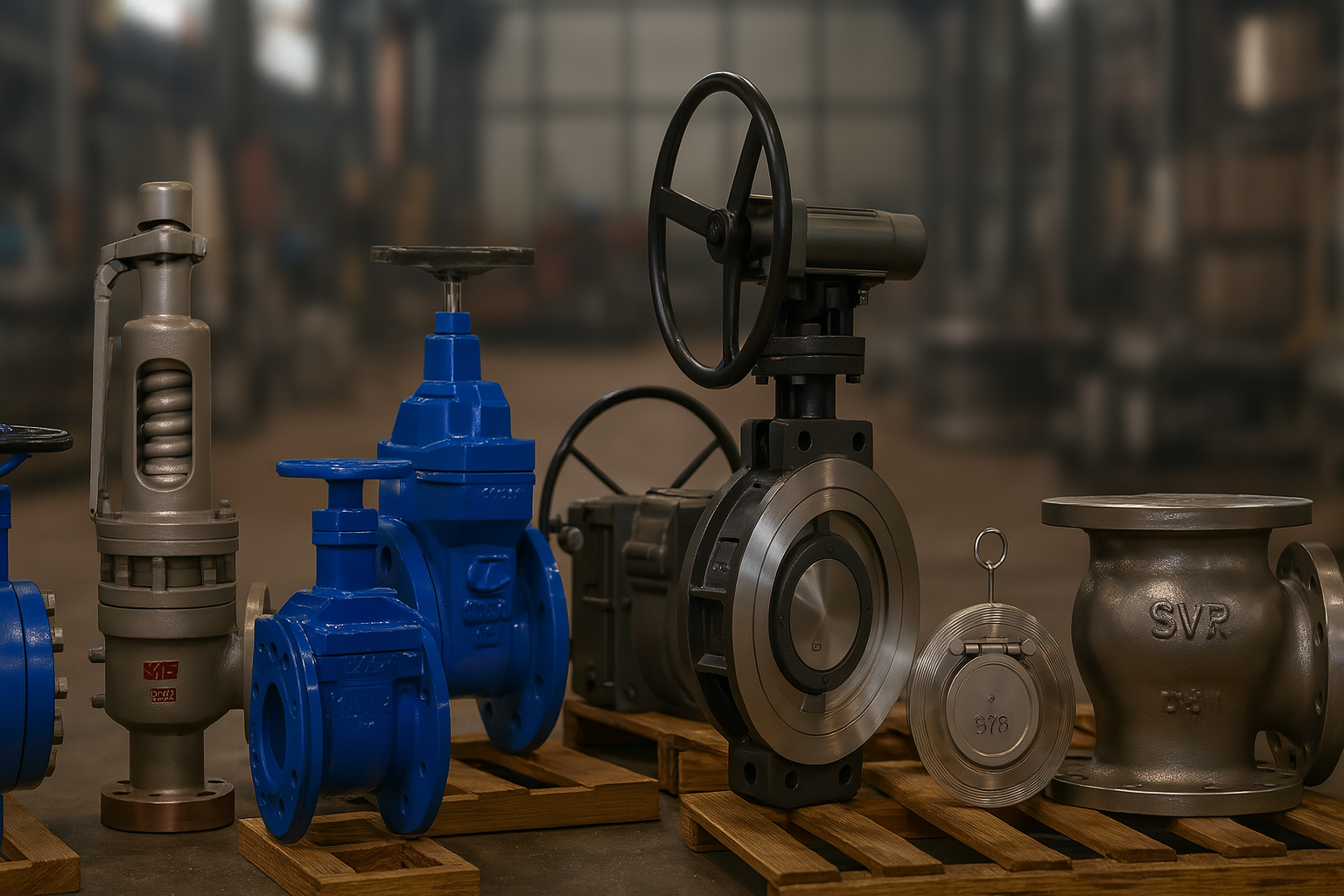

Key Valve Types Used in Saudi Arabia’s Oil and Gas Sector

1. Gate Valves

Gate valves are widely used for isolation in pipeline networks. They offer low-pressure drop and tight sealing when fully closed, making them ideal for upstream and midstream applications.

Common Uses:

- Crude oil pipelines

- Water injection systems

- Wellhead flowlines

Variants:

- Rising Stem

- Non-Rising Stem

- API 6D Pressure Seal Gate Valves

2. Globe Valves

Globe valves regulate flow with precision. They are often found in high-pressure control systems where throttling is essential.

In the oil and gas sector, the performance of valves can impact production rates significantly.

Applications:

- Steam systems

- Refinery pressure regulation

- Flow control in gas dehydration units

3. Ball Valves

Ball valves offer quick shutoff and are suited for both gas and oil service. Their compact design and low torque make them easy to automate.

Popular Types in Saudi Plants:

- Trunnion Mounted Ball Valve

- Floating Ball Valve

- Fully Welded Ball Valve

Why They’re Popular:

- Tight shutoff

- Low maintenance

- Aramco-approved variants available

4. Butterfly Valves

These are used for large-diameter pipelines and are preferred where space and weight are a concern.

Applications:

- Cooling water systems in refineries

- Seawater intake lines in offshore rigs

Options Used:

- High-performance Double Offset

- Lug and Wafer Types

- Fire-safe designs for hazardous areas

5. Check Valves

Check valves prevent backflow, ensuring safety and process integrity.

Saudi Facilities Use:

- Swing Check Valves

- Dual Plate Check Valves

- Piston Check Valves

Both the upstream and downstream sectors of oil and gas rely heavily on these valve technologies.

These are typically installed in pipeline segments that transport oil, gas, or water to avoid contamination and reverse flow.

6. Control Valves

Control valves are critical in downstream processing, especially in refineries and petrochemical units.

Used For:

- Pressure and flow regulation

- Temperature balancing

- Blowdown systems

Common Options:

- Globe-type Control Valves

- Cage Guided Control Valves

- Pneumatic and Electric Actuated Types

Standards & Certifications: What Saudi Oil Projects Require

Saudi Arabia adheres to strict international and local valve standards. Any valve used in an Aramco, SABIC, or Ma’aden project must meet specific technical requirements.

International Standards:

- API 6D / 600 / 602 – Pipeline and refinery-grade valves

- ANSI / ASME B16.34 – Pressure-temperature ratings

- NACE MR0175 – Resistance to H2S (sour gas service)

- BS 5351, ISO 17292 – Ball valves in industrial use

Saudi-specific Requirements:

- Aramco Approval – Mandatory for valves in oil & gas projects

- SABIC Vendor Approval – For petrochemical and downstream use

- SASO Compliance – Ensures product safety for import and use

Make sure the supplier provides test certificates, PMI reports, and QAP documents as part of procurement.

Where These Valves Are Used: Application Areas

Saudi Arabia’s oil & gas industry is segmented into Upstream, Midstream, and Downstream operations. Each stage uses valves differently:

Upstream (Exploration & Production):

- High-pressure gate valves at wellheads

- Check valves in artificial lift systems

- Ball valves for emergency shutoff

Control valves in oil and gas processing can greatly enhance efficiency and safety.

Midstream (Transportation & Storage):

- Fully welded ball valves in cross-country pipelines

- Butterfly valves in tank farms

- Plug valves in loading terminals

Downstream (Refining & Petrochemicals):

- Control valves in cracking units

- Globe valves in hydrogen processing

- Knife gate valves in slurry handling (e.g., sulfur recovery units)

Challenges in Saudi Environments and Valve Requirements

Operating in desert and offshore environments presents unique challenges:

- High ambient temperatures (up to 55°C)

- Sour service (hydrogen sulfide-rich oil/gas)

- Sand and dust that can damage actuators and seals

- Corrosive seawater exposure in offshore platforms

Hence, valves must be manufactured from Duplex SS, Inconel, Monel, Titanium, or corrosion-resistant alloys, depending on the medium.