Blog

Stainless Steel Vs Duplex Valves: Which lasts longer in offshore service?

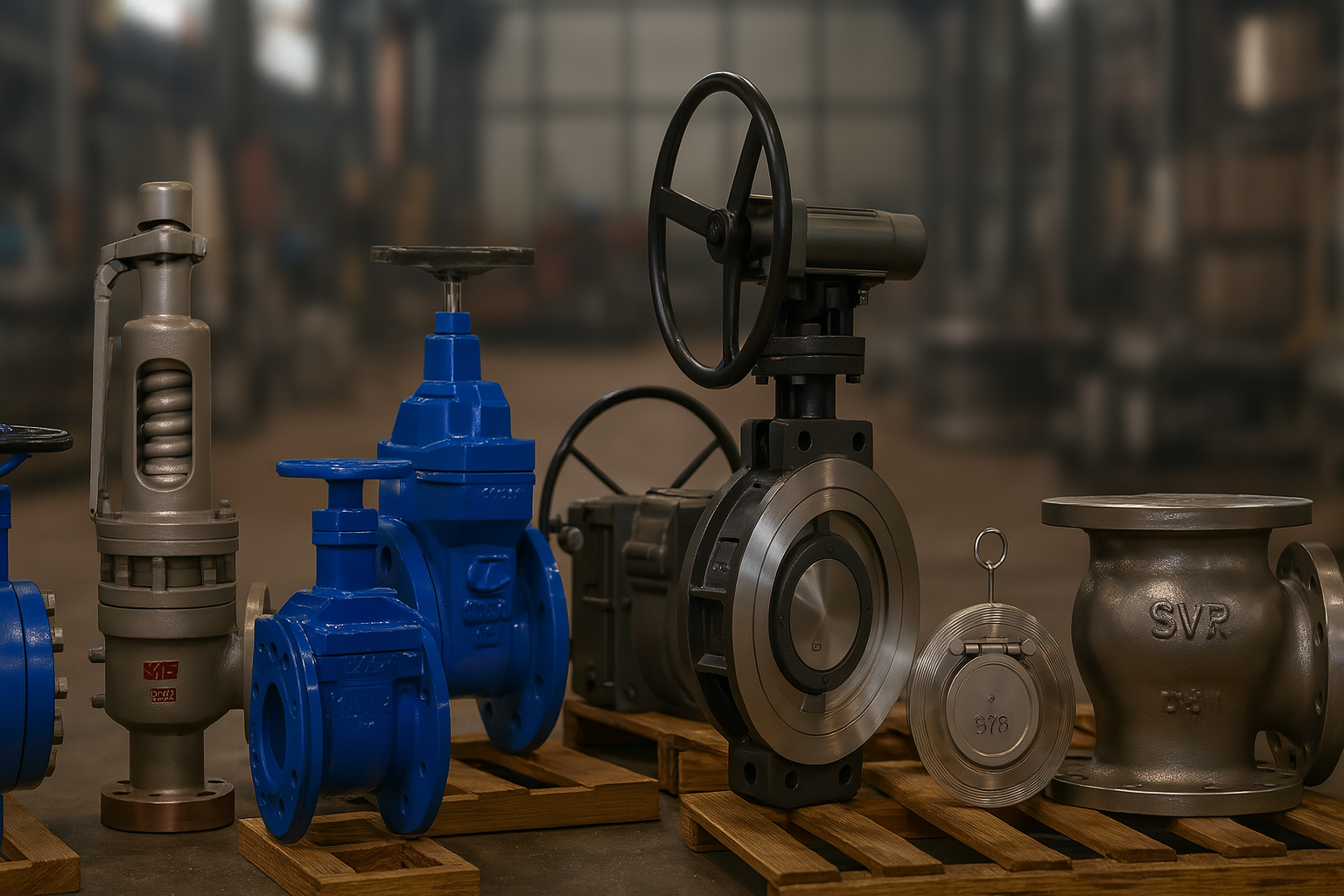

The harsh environmental conditions of the Middle East put a lot of pressure on the offshore oil and gas facilities, seen in the valve materials, which are the most affected because of the combination of high salinity seawater, high ambient temperatures, and continuous exposure to corrosive marine atmospheres. Choosing stainless steel or duplex steel valves in such conditions can thus impact service life, safety, and lifecycle cost significantly.

As a leading manufacturer in Middle East, Middleeast Valve is catering to offshore projects all over the Arabian Gulf where material selection is a matter of safety and reliability. This article elaborates on the performance of stainless steel and duplex valves in offshore conditions and identifies which material is more durable under Middle East operating conditions.

Offshore Service Conditions and Material Challenges in the Middle East

The offshore platforms of the Middle East endure harsher challenges than most other offshore environments as a result of a distinctive combination of environmental and operational factors.

- High Chloride Concentration:

The water of the Arabian Gulf is one of the most chloride-rich sources in the world, thus the risk of pitting and crevice corrosion is elevated considerably. Corrosion of valve bodies, internals, bolting, and sealing surfaces is highly vigorous, particularly in seawater intake and cooling systems.

- Elevated Ambient and Process Temperature:

Long exposure to high temperatures not only accelerates corrosion processes but also increases the material’s vulnerability to stress corrosion cracking (SCC), in particular, to tensile conventional stainless steels.

- Stagnant and Low-Flow Conditions:

Dead legs and intermittent flow that usually occur in offshore piping systems concentrate the corrosion locally. Materials have to be able to resist corrosion even under stagnant seawater conditions.

- Cyclic Pressure and Mechanical Loading:

Offshore valves are subjected to pressure changes and start, stop operations frequently. To avoid cracking or deformation, they must have high mechanical strength and fatigue resistance.

- Restricted Maintenance Access:

Offshore installations are mechanically serviced at extended intervals. Valve materials have to offer long-term performance with minimum inspection and intervention, as maintenance activities are expensive and difficult to organize.

Stainless Steel Valves in Offshore Applications

In general, stainless steel valves are widely used for most applications due to their inherent corrosion resistance and global availability. However, their performance offshore is mostly determined by the type of exposure and operating conditions.

Key Characteristics

- Good resistance to general corrosion

- Moderate mechanical strength

- Vulnerable to chloride, induced pitting and crevice corrosion

- Susceptible to stress corrosion cracking at elevated temperatures

Application Suitability

Stainless steel valves are generally confined to non-critical systems or areas with low exposure. Their service life can be drastically shortened in continuous seawater or open marine environments.

Duplex Valves in Offshore Applications

When the aim is to maintain performance in aggressive offshore conditions, duplex stainless steels are the materials of choice.

Key Characteristics

- Dual-phase microstructure providing superior strength

- High resistance to pitting, crevice corrosion and SCC

- Excellent performance in seawater and chloride-rich environments

- Less wall thickness required due to higher yield strength

Application Suitability

Duplex valves are the norm in seawater systems, firewater networks, pipelines, and hydrocarbon processing units where long-term stability is necessary.

Stainless Steel Vs Duplex Valve: Performance Comparison

| Parameter | Stainless Steel | Duplex |

| Chloride Resistance | Moderate | Excellent |

| Pitting & Crevice Corrosion | High Risk | Very Low Risk |

| Stress Corrosion Cracking | Susceptible | Highly Resistant |

| Mechanical Strength | Moderate | High |

| Offshore Service Life | Limited | Extended |

| Maintenance Requirement | High | Low |

Service Life and Cost Considerations

Duplex Valves may have a higher initial material cost, but they deliver lower lifecycle costs by reducing corrosion, related failures, maintenance downtime and replacement frequency. Stainless steel valves, although cheaper at first, are often required to be frequently inspected and replaced prematurely in offshore environments.

Material Selection Guidelines for Offshore Valve Operations

| Selection Criteria | Stainless Steel Valves | Duplex Valves |

| Seawater Exposure | Suitable only for limited or intermittent exposure | Recommended for continuous seawater service |

| Chloride Concentration | Performs poorly at high chloride levels | Excellent resistance to chloride induced corrosion |

| Operating Temperature | Limited at elevated temperatures due to SCC risk | Performs reliably across wider temperature ranges |

| Pressure & Mechanical Loads | Moderate pressure and static loads | High-pressure and cyclic load applications |

| Corrosion Risk | Higher risk of pitting and crevice corrosion | Minimal corrosion risk in marine environments |

| Maintenance Frequency | Requires frequent inspection and monitoring | Reduced maintenance over long service life |

| Criticality of Service | Non-critical or auxiliary systems | Safety-critical and primary process systems |

| Expected Service Life | Short to medium term | Long-term offshore operation |

| Lifecycle Cost | Lower initial cost, higher maintenance cost | Higher initial cost, lower total lifecycle cost |

In an offshore service environment, valve material selection should primarily concentrate on corrosion resistance, mechanical strength, and operational reliability over a period of time rather than on the initial procurement cost. Duplex valves offer excellent resistance to chloride, induced corrosion and stress corrosion cracking, thus, they are the most appropriate choice for safety, critical offshore systems, whereas Stainless Steel valves can be used in restricted, low exposure situations.

As a leading manufacturer in Middle East, Middleeast Valve is providing engineered valve solutions that support extended long life, have low maintenance requirements and are performance-reliable in challenging marine and offshore environments.