Blog

WHAT IS A NEEDLE VALVE? WORKING PRINCIPLE, TYPES & APPLICATIONS

Middleeast Valve is the well established valve manufacturing company that provide precision made product for the variety of industrial process. Among our wide range of product, we are focused on high quality needle valves renowned for their accuracy, control, and reliability. The purpose of this article is to give an in-depth analysis of what is a needle valve? Working principle, types & applications, enabling you to make an informed choice for your flow control requirements.

What is a Needle Valve?

A needle valve is the flow control valve that has a small port and a threaded, needle pointed plunger. It serve to control or very accurately regulate the flow rate of fluids, particularly in applications wherein accurate adjustments are essential. The distinctive characteristic of this valve is its long, tapering needle-shaped point at the tip of the valve stem, which enters a corresponding seat.

Needle valve are best applied in low flow, high pressure application and permit operator to adjust flow and pressure finely inside pipeline and equipment.

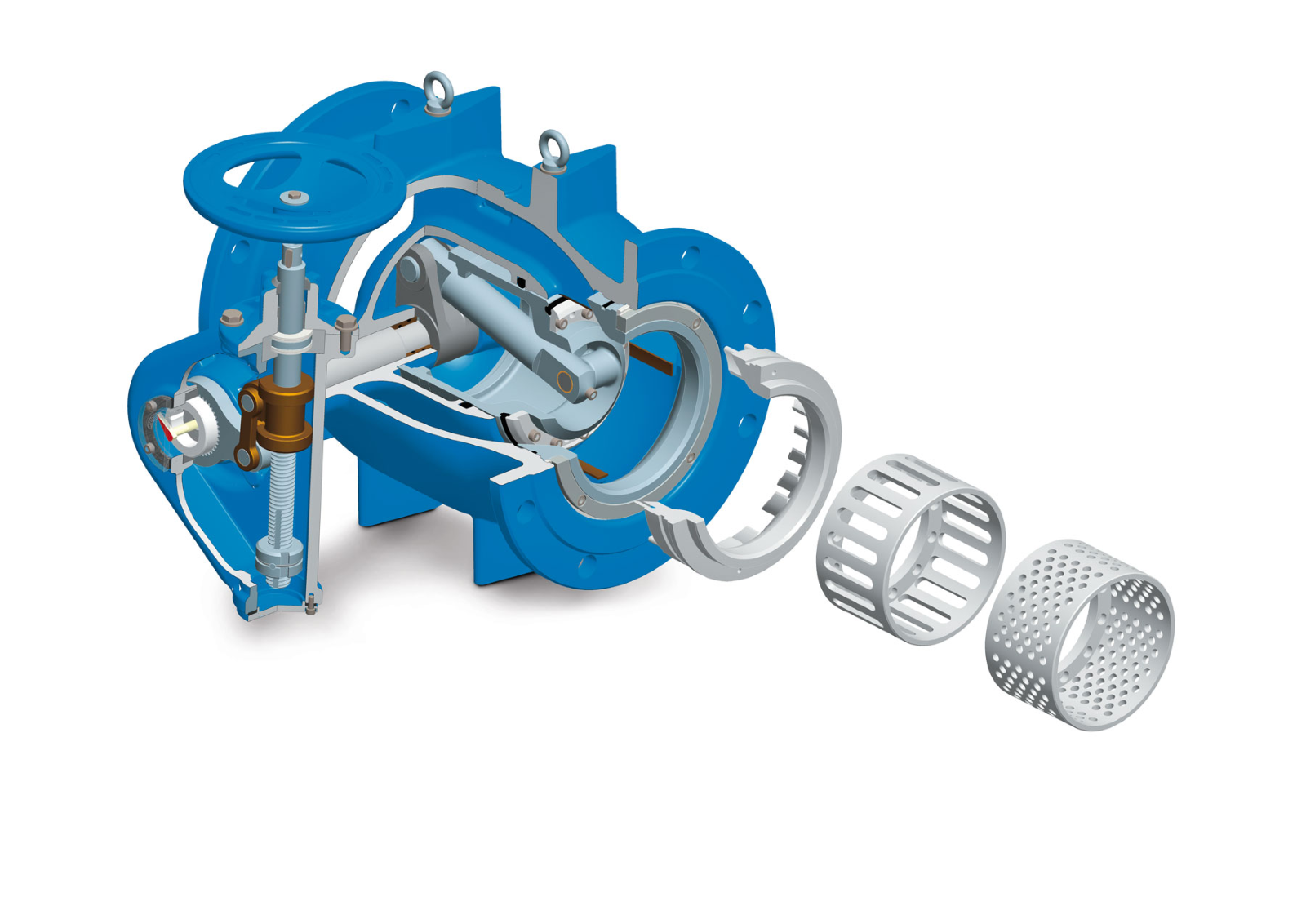

Major Components of the Needle Valve

A knowledge of a needle valve construction facilitate the appreciation of how it works. The primary parts are:

- Valve Body – Constructed with corrosion-resistant materials such as stainless steel, brass, or alloy steel, the body accommodates all other parts.

- Stem/Needle – The tapered, long needle that travels in and out of the seat to regulate flow.

- Seat – Takes the form of the needle and closes off the flow when fully closed.

- Handle/Wheel – Manually operates the valve by rotating the stem.

- Bonnet – Covers the top of the stem and ensures stem alignment.

- Packing – Seals the stem where it passes through the bonnet to prevent leaks.

Working Mechanism of the Needle Valve

The operation of a needle valve is based on its capability to regulate flow through accurate positioning of the needle within the valve seat. When the handle is rotated, the needle travels linearly into or out of the seat. The farther the needle is moved from the seat, the bigger the flow passage becomes and the more fluid is allowed to flow through.

Due to the fine-threaded stem, small turns of the handle translate into very fine control over the flow, so needle valves are best suited for metering duties or where precise flow regulation is required.

Types of Needle Valve

Middleeast Valve has a range of needle valves designed to meet certain industrial requirements. These include:

- Manual Needle Valve – Handwheel operated, used for applications requiring occasional adjustment.

- High-Pressure Needle Valve – Constructed to handle pressures up to 60,000 psi, utilized in hydraulic and test applications.

- Mini Needle Valve – Small package for low-capacity systems and instrumentation lines.

- Angle Needle Valve – Enables flow at a 90° angle, perfect for space-restricted installations.

- Forged Body Needle Valve – Provides improved strength and corrosion resistance, best suited for aggressive environments.

- Double Block and Bleed Needle Valve – Houses two valve and the bleed valve in one package for system isolation and maintenance.

Benefit of Needle Valve

Selecting needle valves from Middleeast Valve provides an array of advantages:

- Accurate Flow Control – Gradual adjustments make it ideal for metering and fine adjustment.

- Leak tight Shut off – Tapered needle and seat offer superior sealing functionality.

- High Pressure and Temperature Resistant – Long lasting materials survive extreme pressures and temperatures.

- Flexible Configuration – Offered in straight, angle, and manifold configurations.

- Compact and Conscientious – Small space requirement with extended life and low maintenance.

Industries Employing Needle Valve

Needle valves are used extensively in various industries such as:

- Oil & Gas – In sampling lines, test instruments, and process control systems.

- Chemical Processing – For precise handling of aggressive fluids and gases.

- Water Treatment – For the control of chemicals and flow in filtration applications.

- Power Generation – In steam and boiler systems for pressure regulation.

Why Is a Needle Valve Needed?

Needle valves are called for wherever fluid flow must be accurately regulated. Unlike ball or gate valves, which are suited for on/off control, needle valves are engineered for throttling service. They are a must in instrumentation systems, sampling lines, and small bore piping, where leakage is minimal and flow rates are critical.

They are most important in application where they must open and close gradually to avoid pressure surges, which will harm sensitive equipment or disturb processes.

Why Choose Middleeast Valve?

We at Middleeast Valve do not simply make valves – we build trust, performance, and value. Here’s why customers around the world select us:

- Uncompromised Quality – We follow international standard such as API and ISO to guarantee consistent performance under all conditions.

- Custom Engineering – Our engineers develop valve solutions that suit particular process requirements.

- Extensive Material Option – From stainless steel to special alloys, we provide a wide range of materials to support various application.

- Prompt Delivery and Support – With local warehouse and prompt customer care we guarantee timely delivery and technical support.

- Proven Track Record – Trusted by major industry in the Middle East, Asia and Africa for over the decade.

When you choose Middleeast Valve, you are not just buying a product—you are investing in performance, reliability, and peace of mind.

Conclusion

Needle valve are the common component of flow control system in the broad variety of industry because of their accuracy, longevity, and versatility. From managing gas flow in analytical instruments to controlling liquid dosing in chemical plants, they deliver unparalleled control and dependability.

We trust this guide has provided you with a good idea of what is a needle valve? Working principle, types & applications and how these small devices are so crucial in process control. At Middleeast Valve, we are delighted to be your go-to partner for your fluid control solutions. Reach out to us today to get the ideal needle valve for your application.