Blog

ADNOC Approved Valves: Technical Specifications EPC Contractors Must Know

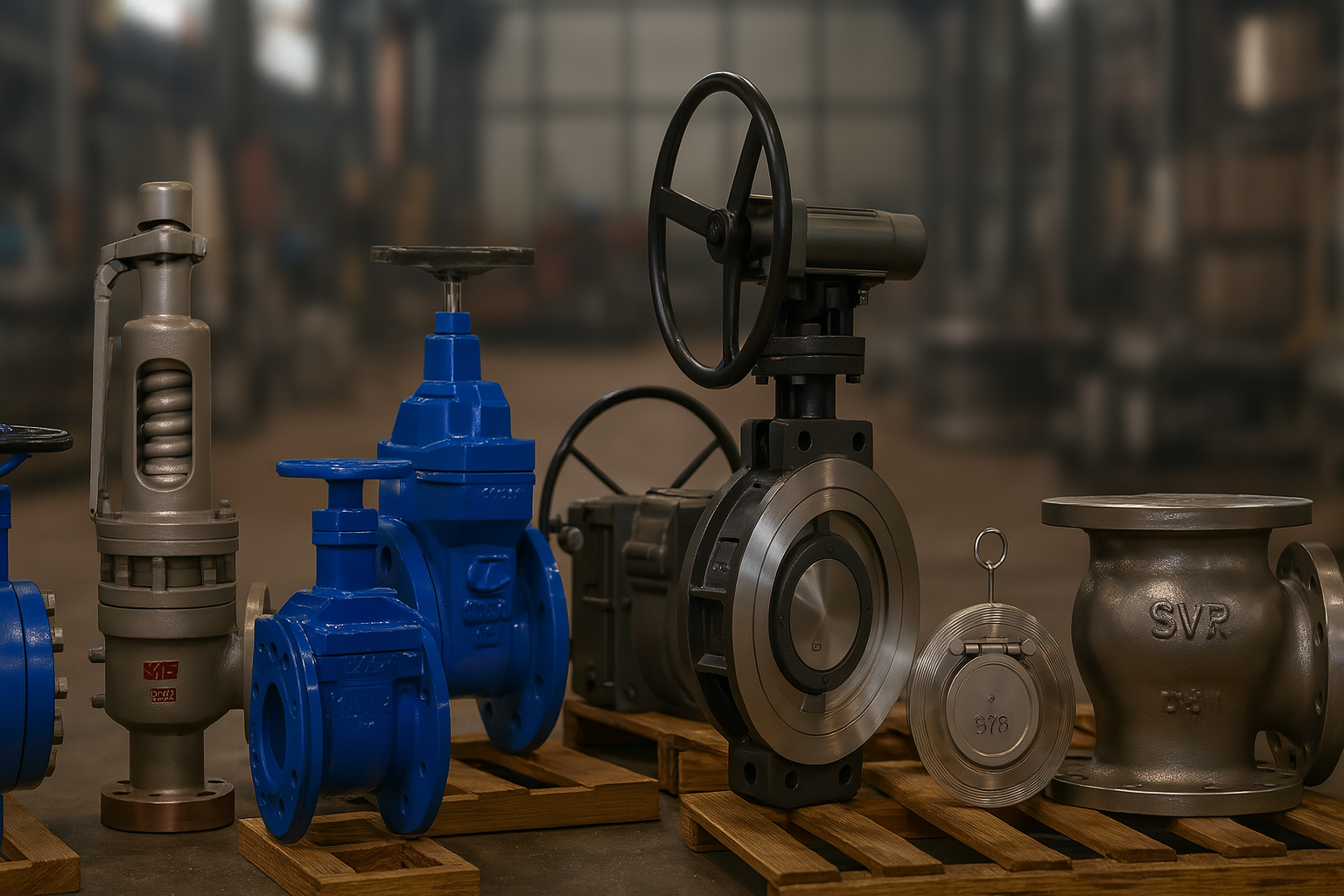

ADNOC approved valves are an essential criterion for oil and gas developments carried out by the Abu Dhabi National Oil Company. ADNOC imposes very high standards from technical and material perspectives so that safety standards can be maintained for long term throughout the upstream, midstream, and downstream sectors. It is necessary for the EPC contractors that they familiarize themselves with the ADNOC standards related to the valve.

The following article presents key technical specification, standard, compliance requirements that need to be taken into consideration by EPC contractors while procuring ADNOC-project valves.

What does ADNOC Valve Approval mean?

The approval of an ADNOC valve means that not only is that valve internationally acceptable, according to API or ASME, but is also acceptable according to an internal engineering standard that is specific within an organization.

Being API certified, a valve may still fall foul of ADNOC if:

- Materials are not from ADNOC-accepted grades

- Documentation is incomplete or inconsistent

- Testing does not meet ADNOC project specifications

Therefore, approval is a technical and procedural requirement.

Reasons Why ADNOC Valve Requirements are Strict

ADNOC operates some of the most strategic oil and gas infrastructural assets in the Middle East. Valve failures can lead to:

- Production losses

- Safety incidents

- Environmental damage

In order to minimize these risks, ADNOC operates stricter controls regarding design margins, material, inspection, and traceability than in the industry standard. This is of particular significance to sour service, offshore, high-pressure applications.

International Standards Applicable for ADNOC Valves

- API Standards

API standards define valve design, performance, testing, and acceptance criteria. ADNOC frequently references API standards as the baseline for:

- Pressure containment

- Sealing performance

- Operational durability

- ASME Standards

The use of ASME standards ensures the control of ratings in terms of pressure and temperature, dimensions of the flange, and material strength values. The conformance of valves to ASME standards ensures the valves are able to operate within certain classes of pressures and temperatures.

The standards set by API and ASME create a technical basis for ADNOC valves.

- API 600- Steel gate valves for refinery and process service

- API 602- Forged Steel Valves For High Pressure Service

- API 6D- Ball and plug valves for pipeline applications

- API 598- Valve inspection and pressure testing

- API 607 / API 6FA- Fire-safe testing of critical isolation valves

These specifications have to be followed compulsorily in ADNOC valves.

ADNOC Valve Materials Requirements

Material selection plays an important consideration within the ADNOC approval process, especially for corrosive, sour, or high-temperature applications.

- Carbon Steel:Grades like ASTM A216 WCB and ASTM A105 are utilized for non-corrosive hydrocarbon fluids in the absence of sour service.

- Stainless Steel: CF8 and CF8M materials are applied where moderate corrosion resistance is required. Hardness limits and chemical composition must meet ADNOC specifications.

- Duplex and Super Duplex: Duplex and super duplex valves are generally used in sour applications, off shore, and in high chlorides because of their higher strength resistance to stress corrosion cracking.

- Alloy Valves: Nickel based or alloy materials are used in conditions of high temperatures, high pressures, or aggressive environments where ordinary steels cannot work.

Testing, Inspection and Certification of ADNOC Valves

ADNOC has strict testing and documentation norms to ensure the quality of the valve.

Testing Requirements:-

- Hydrostatic and shell testing as per API 598

- Seat leakage testing based on valve type and class

- Sour Service Compliance

- Mandatory NACE MR0175 / ISO 15156 compliance

- Verification of hardness and material chemistry

- Fire-Safe Testing

- API 607 or API 6FA certification where required

Documentation

- Material Test Certificates (MTC)

- Quality Assurance Plan (QAP)

- Inspection and Test Plan (ITP)

- Third-party inspection reports

- Inadequate documentation is one of the leading reasons for disqualification.

Typical Compliance Challenges in ADNOC Valve Supply

Major challenges include:

- API-certified valves without ADNOC project documentation

- Incorrect heat numbers or missing material traceability

- Unapproved material substitutions

- Incomplete inspection records

- Early technical review helps prevent these issues.

How EPC Contractors Evaluate Valve Suppliers for ADNOC Projects

EPC contractors assess suppliers based on:

- Compliance history with ADNOC projects

- Manufacturing and testing capabilities

- Quality management systems

- Proven references in UAE oil and gas projects

- Suppliers with prior ADNOC experience face fewer approval risks.

Selecting Valves for ADNOC Projects

Successful valve selection requires:

- Matching valve type to process service

- Verifying applicable API and ASME standards

- Confirming material acceptance and sour service compliance

- Ensuring full documentation readiness before procurement

Early alignment with ADNOC valve requirements reduces delays and rework.

Compliance with ADNOC valve requirements goes beyond the satisfaction of the API standards. The valves should have fewer standards when it comes to material choice, testing, inspection, and documentation in order to be approved. For the EPC contractors, sourcing valves for ADNOC projects from competent manufacturers can lower the chances of approval risks and supports long-term operational reliability. Selecting ADNOC approved valves from the very start is critical for project success in the UAE oil and gas sector.