Blog

DUPLEX VALVE VS. SUPER DUPLEX VALVE: WHAT’S THE DIFFERENCE?

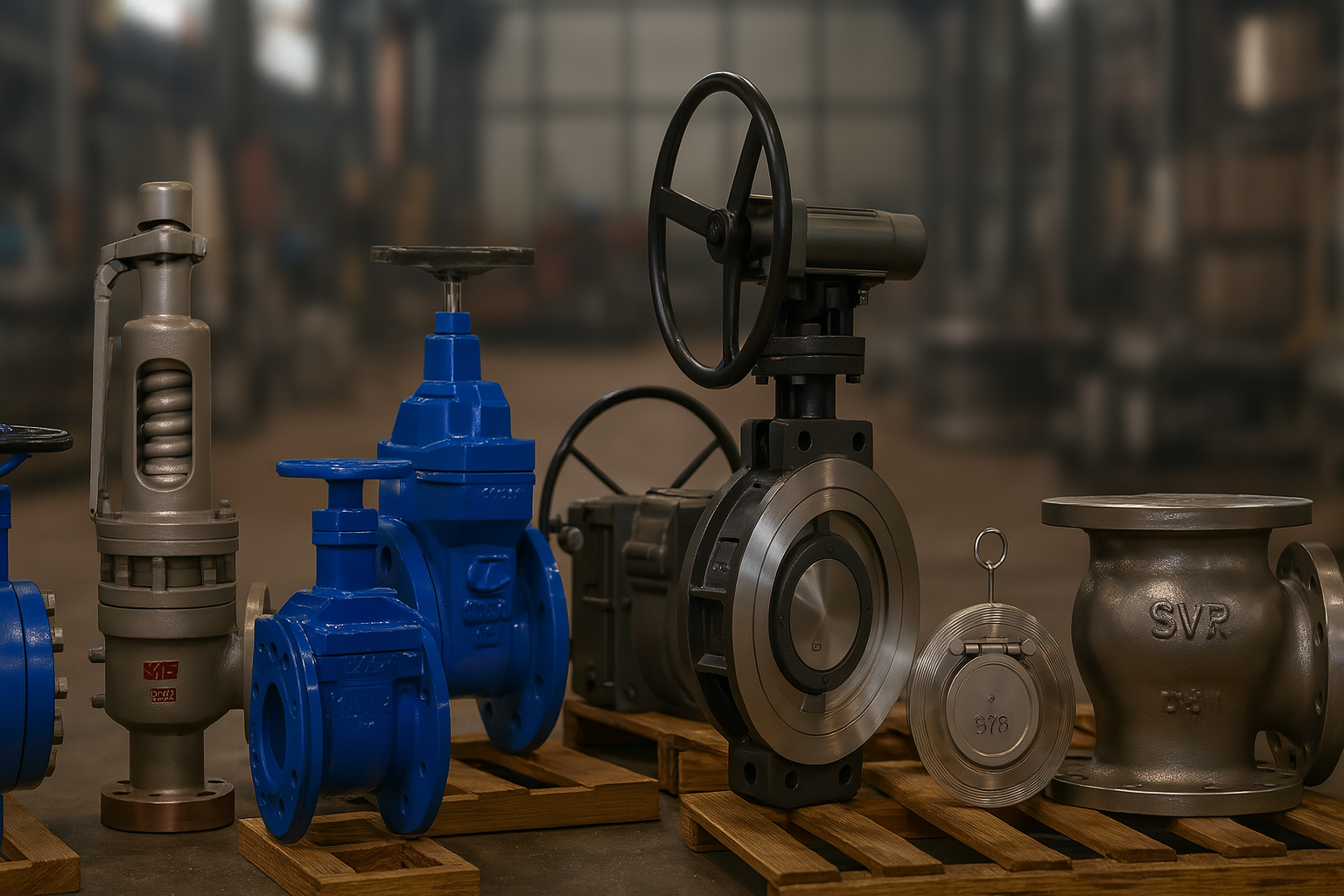

Middleeast Valve deliver reliable industrial valve made with strength, durability and high performance in high corrosiveness and high pressure. In all industries like oil & gas, petrochemical and shipping, the selection of the valve material can determine long term reliability or system failure even before its design life. Duplex and Super Duplex stainless steel are two material commonly used due to their resistance for corrosion prevention processes. This leads us to the crucial question that procurement team and engineer typically as- Duplex Valve vs. Super Duplex Valve: What’s the Difference?

The key to understanding the difference lies in making the correct choice of valve according to the intended application, environmental requirement and mechanical specification. Though both material are highly corrosion resistant and have high mechanical strength, their makeup, performance and cost differ significantly.

Definition

Duplex valve is constructed from duplex stainless steel, which is ferritic and austenitic stainless steel alloy. It has a two phase structure with greater strength and stress corrosion cracking resistance than usual stainless steel.

Super Duplex valve consist of super duplex stainless steel which is richer in chromium and molybdenum content and higher in nitrogen content. This provide superior resistance against corrosion especially pitting corrosion and crevice corrosion, and much higher level of mechanical strength.

Major Components of Duplex and Super Duplex Valve

Although the materials are different, all major components for duplex and super duplex valves are the same:

- Body and Bonnet: Made of duplex or super duplex stainless steel, pressure-proof and corrosion-proof.

- Stem: Heavy stem for actuation and valve operation.

- Ball/Disc/Gate: Flow-controlling element (based on valve type), needing high-precision machining and high corrosion resistance.

- Seats and Seals: Usually made of PTFE, graphite, or metal, selected according to compatibility with valve material and environment.

- Actuator (when required): Manual, pneumatic, electric, or hydraulic, based on application needs.

Working Mechanism

The working mechanism of the duplex and super duplex valves will be based on valve type-ball, gate, globe, butterfly, or check—but the material strength, being a vital factor in the material, will possess the capability to withstand harsh working conditions.

Example:

A valve is opened or closed in a duplex ball valve by turning a ball with a bore passing through it.

In duplex gate valves, a gate reciprocates between two seats to restrict flow.

Super duplex globe valves control flow by raising a plug above a seat, appropriate for throttling services.

Though their mechanical working is the same as any other valve class, the difference with duplex and super duplex valves is that they will not deform, corrode, or fail with hostile fluids, high pressure, and high temperature.

Benefits

- Sufficient resistance to corrosion by seawater and chloride atmospheres.

- Greater strength than austenitic stainless steel.

- Less costly than super duplex alternatives.

- Improved weldability than ferritic steel.

- Improved pitting, crevice corrosion, and stress corrosion cracking resistance.

- Improved mechanical strength, nearly twice the strength of austenitic stainless steel.

- Greater service life in extremely aggressive conditions.

- Improved performance at extreme temperature and pressure conditions.

Industries Using Duplex and Super Duplex Valve

- Oil and Gas: Used in offshore platform and refinery facilities.

- Chemical and Petrochemical: Withstanding corrosive acids and gases.

- Desalination Plants: Withstanding the effect of high-chloride environments.

- Marine Industry: Excellent performance in saltwater use.

- Pulp and Paper Industry: Withstanding bleaching agents and process chemicals.

- Power Generation: Withstanding steam and corrosive boiler chemicals.

Why Are They Necessary?

Valves used in corrosive service are susceptible to stress corrosion cracking, erosion, and mechanical wear. Wrong material selection may lead to:

- Greater degradation of valve parts.

- Leaks or system pressure loss.

- Expensive shutdowns for replacement or maintenance.

Duplex and super duplex valves must be supplied to provide system reliability, safety, and adherence to world standards. Their resistance to corrosion, cracking, and high pressures makes them unavoidable in aggressive operating conditions. Super duplex, in fact, is preferred where even duplex steel is unacceptable.

Duplex Valve vs. Super Duplex Valve: What’s the Difference? mainly differ in their chemistry and performance. Super duplex is more chromium-rich (24–26%), more molybdenum content (3–5%), with nitrogen content increasing greatly, dramatically increasing its resistance to corrosion as well as its mechanical strength. Thus, super duplex is available for the harshest conditions, while duplex is a cheap, balanced answer for moderately hard applications.

Why Buy from Middleeast Valve

We don’t simply provide valves at Middleeast Valve, we provide reliability, engineering assistance, and specification from after-sales. Let’s find out how we’re an ideal supplier worldwide:

- Material Authenticity: We manufacture all our duplex and super duplex valves with traceable certified raw material.

- Compliance and Testing: Our products comply with global standards like ASTM, API, ASME, and ISO. All of our products are thoroughly tested in the form of hydrostatic, NDT, and PMI (Positive Material Identification).

- Customization: We provide customized solutions for various industries and applications and assure the appropriate material and design fit.

- Global Reach: With a strong supply chain and logistics network, we distribute in the Middle East, Asia, and Africa cost-effectively.

- Competitive Pricing: Affordable with uncompromising quality. With decades of association with the industry, we pass savings directly on to our customers.

Duplex Valve vs. Super Duplex Valve: What’s the Difference? isn’t so much material content—it’s the appropriateness for application, operational life, and cost return. Middleeast Valve makes the decision for you with confidence, supplying valves that fulfill the high demands of the requirements of the day.