Blog

WHAT IS A STEAM TRAP? TYPES AND WORKING PRINCIPLE

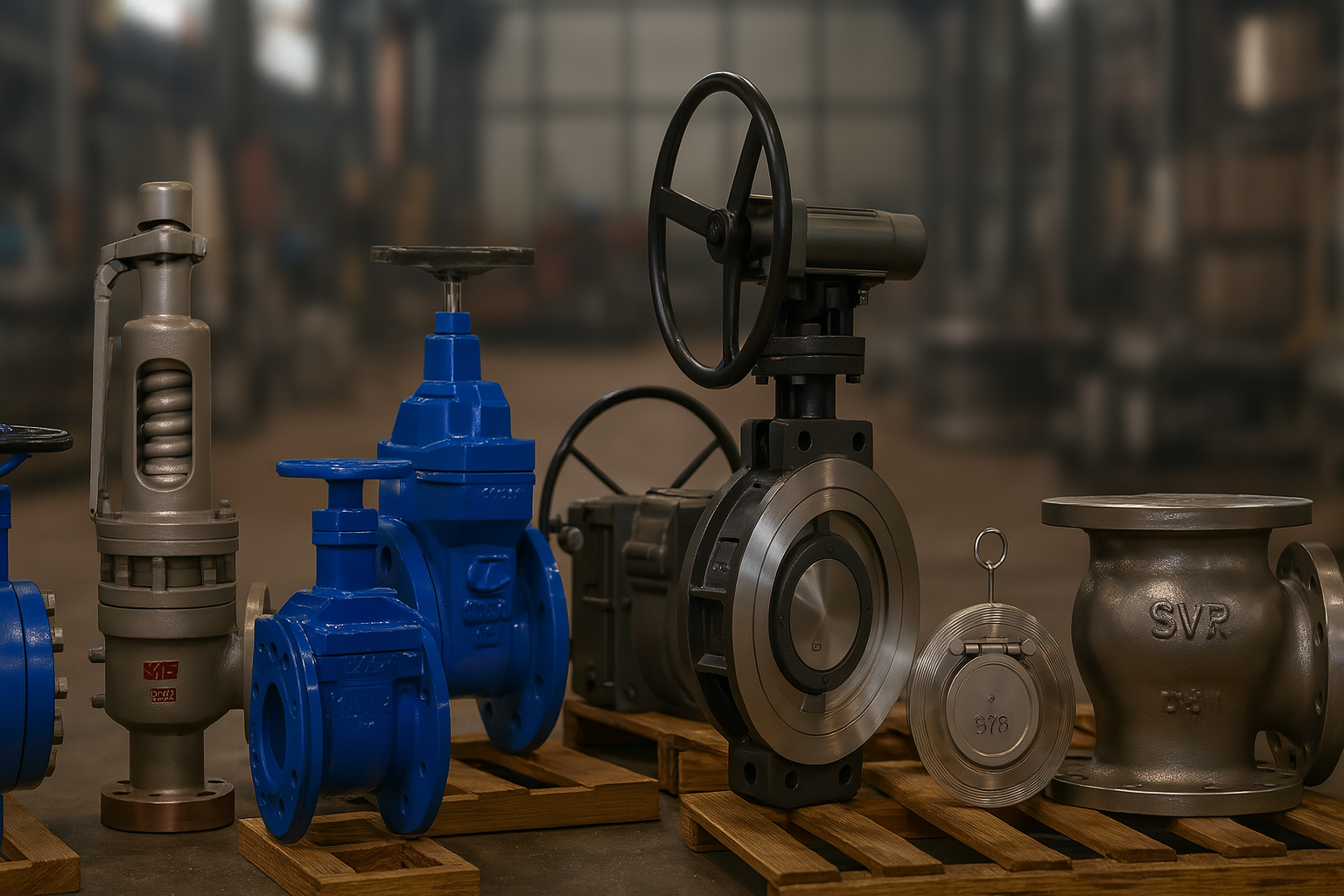

Middleeast Valve is the top supplier of high-performance industrial valves. Perhaps the single most critical component of steam system hardware—undervalued yet crucial to safety and efficiency—is the steam trap. If you ever wondered, “What Is a Steam Trap? Types and Working Principle,” then you’re not alone. Engineers, maintenance personnel, and operating personnel in facilities who perform maintenance on steam-powered systems across a range of industries need to be knowledgeable about steam traps.

Steam traps provide effective steam system operation by draining off excess condensate and non-condensable gases while maintaining live steam. If these devices function well, they maximize energy usage, save costly equipment, and provide process uniformity. They can create energy loss, equipment wear, and safety issues if they malfunction.

What is a Steam Trap?

A steam trap is an automatic valve which can admit condensate (water which is formed when steam relinquishes heat) and non-condensable gases such as air for discharge but not steam. It is the most vital component of a steam distribution system. Steam traps function through temperature, pressure, or density differences between the steam and the condensate.

Their basic function is to be simple but control their job: control steam, drain water. They do not have to be there, or condensate would build up in equipment and piping, lowering heat efficiency, inducing corrosion and, in worst-case scenarios, such risks as water hammer (temporary pressure surges that can burst pipes).

Key Elements of a Steam Trap

- Valve and Seat: The innermost pieces that open and close to release condensate or block steam passage.

- Body: The outer casing that holds inner components; made to handle heat and pressure.

- Actuation Mechanism: Varies by model (float, bucket, disc, thermostatic element, etc.) and controls when to open/close.

- Inlet and Outlet Ports: For fluid entry and exit.

- Strainer (optional): Some models include strainers to filter debris in order to prevent clogging.

Working Mechanism

Steam traps work by physical differences between steam, condensate, and gases. The actuating mechanism recognizes these differences and opens or closes the valve. The three primary principles they work on are:

- Difference in density (Mechanical traps)

- Difference in temperature (Thermostatic traps)

- Difference in velocity and pressure (Thermodynamic traps)

Types of Steam Traps

1. Mechanical Steam Traps

They work on the principle of steam and water density difference.

Float Trap: Uses a float which rises with condensate level, allowing discharge valve to open and discharge water. Is ideal for continuous discharge.

Inverted Bucket Trap: Uses an inverted bucket floating in steam but descending in water, opening or closing the discharge valve. They are heavy-duty and wear-resistant and are suitable for medium-pressure systems.

2. Thermostatic Steam Traps

Operates on principle of temperature difference.

Bimetallic Traps: Use two metals with different expansion capacities. When cooled by condensate, they contract and open the valve.

Balanced Pressure Traps: Use a liquid-filled bellows that changes with temperature fluctuations. They open when cooler condensate is present.

Thermostatic traps are best suited for situations where frequent discharge is acceptable, such as tracing lines.

3. Thermodynamic Steam Traps

They are pressure and velocity sensitive.

Disc Trap: A flat disc is lifted by condensate and closed by high-speed steam. They’re small, tough, and function well under high pressures.

They are best suited for outdoor use because they’re resistant to freezing and simple to build.

Advantages of Steam Traps

Steam traps offer a wide range of benefits:

- Energy Efficiency: Minimize live steam loss, maximizing fuel utilization.

- Safety: Avoids pressure buildup and water hammer.

- Protect Equipment: Shield heat exchanger, turbine and pipeline from water induced damage.

- Maintenance-Free Operation: Most steam traps are self acting and can function for years without maintenance.

- System Efficiency: Offers stable pressure and temperature, ensuring ideal process conditions.

Industries Using Steam Traps

- Oil and Gas: Steam traps are used in heat exchangers, tracing systems, and separation processes.

- Textile Industry: For drying textiles and dye processing.

- Chemical and Petrochemical: Used for safe handling of volatile materials under conditions of steam heat.

- Power Generation: Used in turbines, condensers, and steam distribution systems.

Why Steam Traps Are Necessary

If condensate and gas are not removed from the steam system, the following can happen:

- Water Hammer: Sudden pressure bursts that can destroy pipes, valves, and fittings.

- Corrosion: Leaky condensate creates a corrosive environment.

- Reduced Efficiency: Condensate slows down heat transfer, slowing processes and wasting energy.

- Safety Risks: System imbalance or ruptured pipes may pose significant risks to equipment and human life.

Accurate installation of the appropriate steam trap maintains the system at its optimal performance without inflicting damage and system disruption.

Conclusion

Knowing What Is a Steam Trap? Types and Working Principle is essential to the proper functioning of steam-based systems. Whether you are running an industrial facility or designing a new system, choosing the right steam trap matters a great deal when it comes to safety, efficiency and expense.

Middleeast Valve is pleased to provide high quality steam trap that facilitate dependable operation, energy saving, and prolong equipment life. Our commitment to customer satisfaction, technical support and quality makes us the choice valve supplier for companies globally.