- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Description

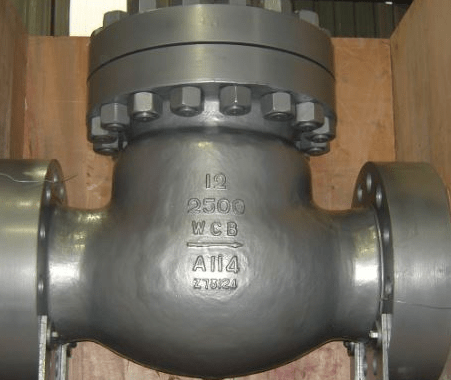

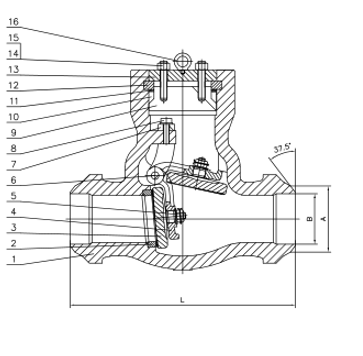

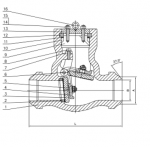

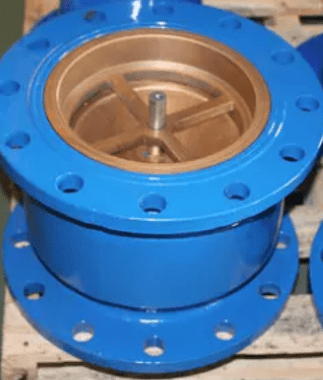

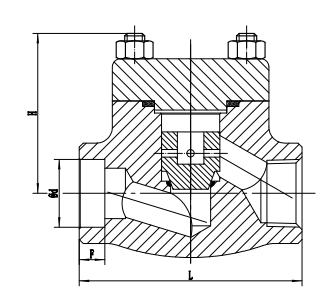

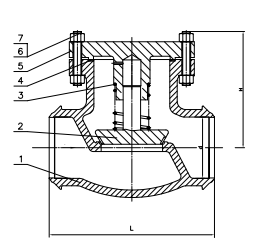

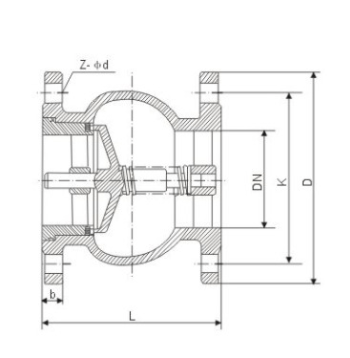

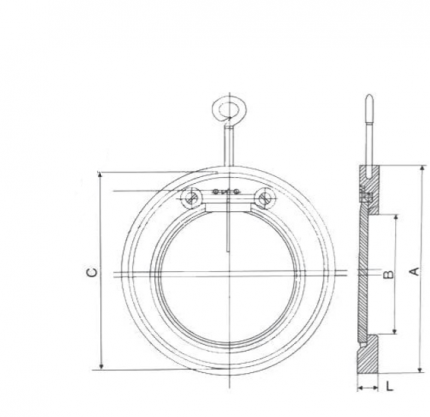

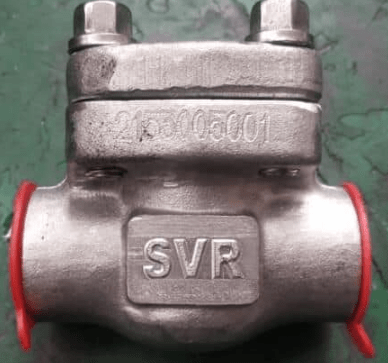

Pressure Seal Check Valve

A pressure seal check valve is a type of check valve that uses a pressure seal to prevent backflow. The valve features a pressure-assisted seal that is designed to close tightly against the valve seat, preventing backflow and ensuring a tight seal. These valves are typically used in high-pressure and high-temperature applications, such as power plants and chemical processing plants. They are also commonly used in pipelines and other fluid systems where a tight seal is required to prevent leakage.

[expander_maker id=”1″ more=”Read more” less=”Read less”]

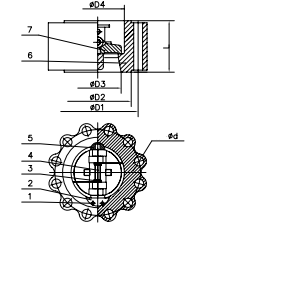

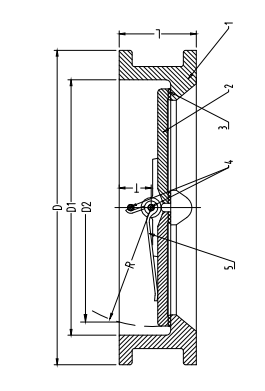

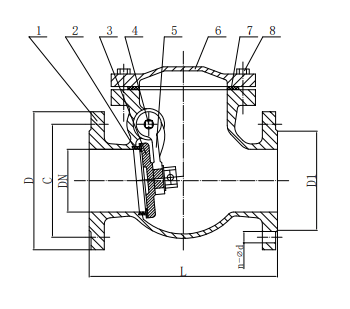

Parts

- Body

- Disc

- Seat

- Hinge

- Spring

- Cover

- Yoke

- Pressure Seal

Advantages

- These valves are designed to withstand high pressure and temperature conditions, making them ideal for use in power plants, chemical processing plants, and other high-pressure applications.

- The pressure-assisted seal on these valves provides a tight seal against the valve seat, preventing backflow and ensuring that there is no leakage.

- These valves have relatively simple designs, with few internal moving parts, which makes them relatively easy to maintain and repair.

- They are typically made of high-quality materials such as stainless steel or alloy, which makes them durable and resistant to wear and tear.

- These valves typically have a compact design, which allows them to be easily installed in pipelines and other fluid systems.

- These valves are known for their reliability, as they are designed to operate with a high degree of accuracy and repeatability.

- The pressure seal design allows for low opening and closing torque, reducing the stress on the actuator.

- They can be actuated by a simple pneumatic or hydraulic actuator, making them easy to control and automate.

- Due to the pressure seal design, these valves typically have a longer life span than traditional check valves.

Industries which use them

- Power Generation Plants

- Oil and Gas Industry

- Chemical Processing Industry

- Pharmaceutical Industry

- Paper and Pulp Industry

- Food and Beverage Industry

- Marine Industry

Applications

- These valves are used to control the flow of steam in power plants, industrial boilers, and other high-pressure steam systems.

- These valves are used to control the flow of water in pipelines, treatment plants, and other water systems.

- They are used to control the flow of crude oil, natural gas, and other fluids in pipelines and processing plants.

- These valves are used to control the flow of corrosive and hazardous chemicals in chemical processing plants.

- These valves are used to control the flow of liquids and gases in sterile environments in pharmaceutical manufacturing.

- They are used to control the flow of fluids in waste water treatment plants.

- These valves are used to control the flow of feedwater in boilers, and other high-pressure systems.

- Pressure seal check valves are used to control the flow of water in fire protection systems.

- These valves are used to control the flow of compressed air in pneumatic systems.

[/expander_maker]