- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Air Release Valve Suppliers in Saudi Arabia: Eliminate Trapped Air for Smooth System Operation

Middleeast valve is the top Air release valve suppliers in Saudi Arabia. It is also known as an air vent valve or air relief valve, is a mechanical device used in various fluid systems, such as water supply networks, pipelines, and industrial processes, to automatically release trapped air or gas from the system.

Main Components of an Air Release Valve:

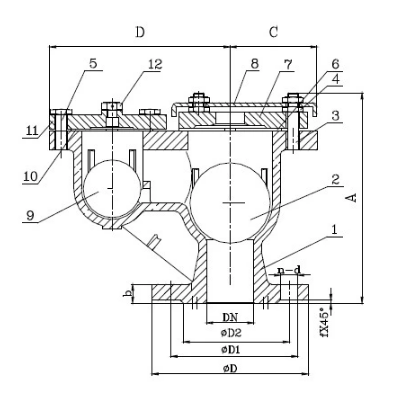

1)Valve Body – The core part containing all the parts.

2)Float – The floating part that comes up with the accumulation of air or gas.

3)Orifice – A tiny opening through which air or gas is released when the float comes up.

4)Seal – Prevents the valve from getting opened if there is no air in the pipeline.

Working Mechanism:

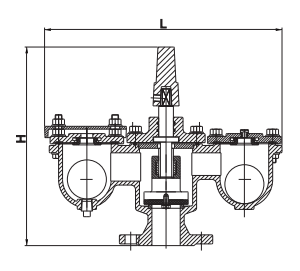

The air release valve work by using float mechanism to sense air or gas accumulation. As air is trapped in pipeline, the float goes up, opening the valve and releasing air. After releasing the air, the float fall, and the valve close, keeping system sealed and efficient.

Benefits of Utilizing Air Release Valve:

1)Avoids System Damage: Prevents airlocks that can harm pumps and pipelines.

2)Enhanced Efficiency: Guarantees the system runs at maximum capacity by eliminating trapped air.

3)Self-activating operation: Self-starting design for minimal human intervention.

4)Long-lasting: Designed to last and withstand a range of fluid and pressure conditions.

Types:

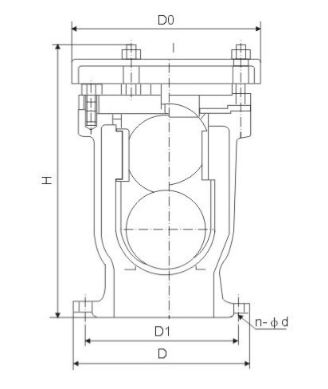

1)Single orifice air release valve

2)Double orifice air release valve

3)Double orifice kinetic air release valve

Description:-

Available materials: CF8M, CF8, SS316, CF8M, WCB, WC6, WCC, LCB, LCC, SS304, SS316

Class:150-300

Pressure: PN6 to PN40

Size:1/2”-8”

End: flanged, threaded