- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

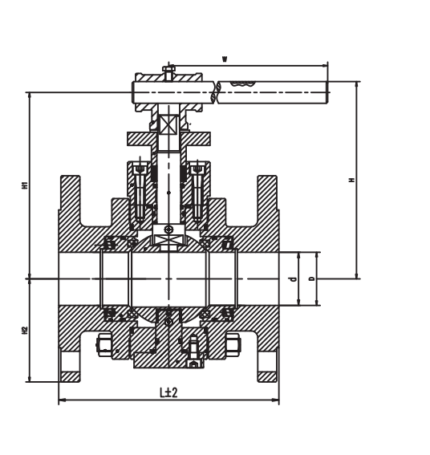

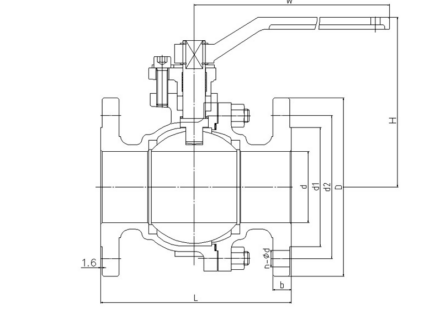

Alloy Ball Valve

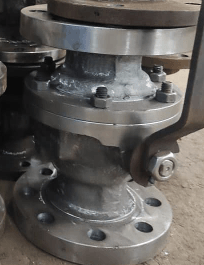

Middleeast valve is a top Alloy Ball Valve Supplier in UAE. We supply to cities like Dubai, Abu Dhabi, Kalba, and Masfut. An alloy ball valve is a type of valve used to control the flow of fluids in various industrial processes. It’s designed with a round or spherical ball-shaped disc that has a hole (port) through its center. The valve operates by rotating this ball to either allow fluid to flow through the hole (open position) or block the flow by aligning the hole perpendicular to the pipe (closed position).

When the ball valve is in the open position, the ball’s hole is aligned with the pipe, allowing fluid to pass through. When the valve is closed, the ball is rotated 90 degrees, blocking the flow by positioning the hole perpendicular to the pipe. The lever or handle used to operate the valve provides a clear visual indication of whether the valve is open or closed.

Middleeast valve is the magnificent Alloy Ball Valve Supplier in UAE and primary function of an alloy ball valve is to regulate the flow of fluids (liquids or gases) through pipelines or process systems. By turning the ball inside the valve, the operator can control the flow rate, start or stop the flow, and even redirect it. It provides a quick and efficient method of controlling fluid flow.

Advantages

Bi directional flow

Good sealing

Durability

Quick operation

Industries

Oil and Gas: They are used in exploration, drilling, refining, and distribution of oil and gas.

Chemical Processing: For controlling the flow of various chemicals and corrosive substances.

Water Treatment: In municipal water systems, wastewater treatment, and desalination plants.

Power Generation: In power plants for regulating water and steam flow.

Petrochemicals: In the production and handling of petrochemical products.

Automotive: In manufacturing processes and coolant systems.