- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

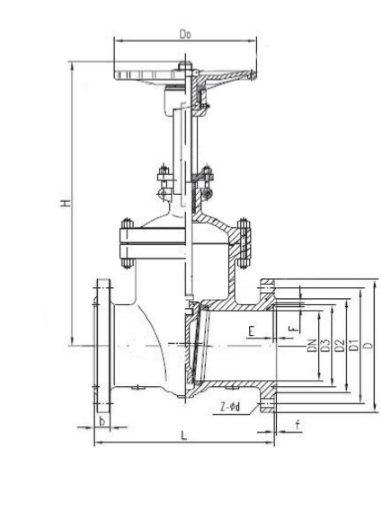

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

- 1 Piece Ball Valve3 products

- 1 Piece Cast Iron Screwed Ball Valve1 product

- 1 Piece Flanged Ball Valve1 product

- 1 Piece Screwed Ball Valve1 product

- 2 Piece Ball Valve3 products

- 2 Piece Cast Steel Ball Valve1 product

- 2 Piece Flanged Ball Valve1 product

- 2 Piece Forged Steel Ball Valve1 product

- 2 Piece Screwed Ball Valve1 product

- 3 Piece Ball Valve3 products

- 3 Piece Cast Iron Ball Valve0 products

- 3 Piece Cast Steel Ball Valve1 product

- 3 Piece Flanged Ball Valve1 product

- 3 Piece Forged Steel Ball Valve1 product

- 3 Piece Screwed Ball Valve1 product

- 3 Way Converging and Diverging Control Valve1 product

- 3 Way plug Valve1 product

- Air Release Valve3 products

- Alloy 20 Ball Valve2 products

- Alloy 20 Butterfly Valve2 products

- Alloy 20 Check Valve2 products

- Alloy 20 Gate Valve1 product

- Alloy 20 Globe Valve1 product

- Alloy 20 Valve8 products

- Alloy Dual Plate Check Valve1 product

- Alloy Floating Ball Valve1 product

- Alloy Globe Valve0 products

- Alloy Lug butterfly Valve1 product

- Alloy Swing Check Valve1 product

- Alloy Trunnion Ball Valve1 product

- Alloy Wafer Butterfly Valve1 product

- Aluminium Bronze Ball Valve2 products

- Aluminium Bronze Butterfly Valve2 products

- Aluminium Bronze Check Valve2 products

- Aluminium Bronze Dual Plate Check Valve1 product

- Aluminium Bronze Floating Ball Valve1 product

- Aluminium Bronze Gate Valve1 product

- Aluminium Bronze Globe Valve1 product

- Aluminium Bronze Lug Butterfly Valve1 product

- Aluminium Bronze Swing Check Valve1 product

- Aluminium Bronze Trunnion Ball Valve1 product

- Aluminium Bronze Valve8 products

- Aluminium Bronze Wafer Butterfly Valve1 product

- Aluminum Bronze Globe Valve0 products

- Angle Globe Valve1 product

- API 6A Ball Valve0 products

- API 6A Check Valve2 products

- API 6A Gate Valve3 products

- API 6A Swing Check Valve1 product

- API 6A Valves5 products

- API Gate Valve0 products

- Balancing Valve1 product

- Ball Float Steam trap1 product

- Ball Valve26 products

- Bellow Safety Valve1 product

- Bellow Seal Gate Valve1 product

- Bellow Seal Globe Valve4 products

- Bidirectional Knife Gate Valve1 product

- Bimetallic Steam Trap1 product

- Bronze Butterfly Valve1 product

- Bronze Check Valve2 products

- Bronze Dual Plate Check Valve1 product

- Bronze Flanged Gate Valve1 product

- Bronze Flanged Globe Valve1 product

- Bronze Floating Ball Valve1 product

- Bronze Gate Valve1 product

- Bronze Gate Valves2 products

- Bronze Globe Valve1 product

- Bronze Globe Valves2 products

- Bronze Swing Check Valve1 product

- Bronze Valve8 products

- Bronze Wafer Butterfly Valve1 product

- Butterfly Valve9 products

- Carbon Steel Bellow Seal Globe Valve1 product

- Carbon Steel Globe Valve1 product

- Cast Floating Ball Valve0 products

- Cast Iron and Cast Steel Ball Valve4 products

- Cast Iron Diaphragm Valve1 product

- Cast Iron Globe Valve1 product

- Casting Floating Ball Valve1 product

- Casting Trunnion Ball Valve1 product

- Check Valve9 products

- Concentric Butterfly Valve1 product

- Connection lift Plug Valve1 product

- Control Valve15 products

- Conventional Safety Valve1 product

- Cryogenic Ball Valve1 product

- Cryogenic Check Valve1 product

- Cryogenic Emergency Cut Off Valve1 product

- Cryogenic Gate Valve1 product

- Cryogenic Long Stem Globe Valve1 product

- Cryogenic Pneumatic Actuated Globe Valve1 product

- Cryogenic Short Stem Globe Valve1 product

- Cryogenic Steam Jacket Globe Valve1 product

- Cryogenic Valve9 products

- Diaphragm Valve2 products

- Direct Acting Pressure Reducing Valve1 product

- Double Block and Bleed Ball Valve1 product

- Double Disc Gate Valve1 product

- Double Eccentric Butterfly Valve1 product

- Double Flanged Butterfly Valve1 product

- Double Orifice Air Release Valve1 product

- Double Orifice Kinetic Air Valve1 product

- Dual Plate Check Valve2 products

- Dual Plate Lug Check Valve1 product

- Dual Plate Wafer Check Valve1 product

- Ductile Iron Diaphragm Valve1 product

- Ductile Iron Globe Valve1 product

- Duplex Ball Valve2 products

- Duplex Basket Strainer1 product

- Duplex Butterfly Valve2 products

- Duplex Check Valve2 products

- Duplex Dual Plate Check Valve1 product

- Duplex Floating Ball Valve1 product

- Duplex Gate Valve1 product

- Duplex Globe Valve1 product

- Duplex lug Butterfly Valve1 product

- Duplex Swing Check Valve1 product

- Duplex Trunnion Ball Valve1 product

- Duplex Valve8 products

- Duplex Wafer Butterfly Valve1 product

- Eccentric Plug Valve1 product

- Electric 3 Way Control Valve1 product

- Electric Actuated 2 Piece Ball Valve3 products

- Electric Actuated 2 Piece Flanged Ball Valve1 product

- Electric Actuated 2 Piece Screwed Ball Valve1 product

- Electric Actuated Ball Valve9 products

- Electric Actuated Butterfly Valve3 products

- Electric Actuated Casting Trunnion Ball Valve1 product

- Electric Actuated Control Valve6 products

- Electric Actuated Floating Ball Valve1 product

- Electric Actuated Forged Trunnion Ball Valve1 product

- Electric Actuated Gate Valve1 product

- Electric Actuated Globe Valve1 product

- Electric Actuated Lug Butterfly Valve1 product

- Electric Actuated Three Piece Ball Valve1 product

- Electric Actuated Three Way Ball Valve1 product

- Electric Actuated Trunnion Ball Valve3 products

- Electric Actuated Valve16 products

- Electric Actuated Wafer Butterfly Valve1 product

- Electric Cage Type Control Valve1 product

- Electric Control Valve0 products

- Electric Double Seat Control Valve1 product

- Electric Globe Control Valve1 product

- Electric O-type Shut off Control Valve1 product

- Electric Single Seat Control Valve1 product

- Expanding Gate Valve1 product

- Flanged Knife Gate Valve1 product

- Flanged Triple Offset Butterfly Valve1 product

- Flanges6 products

- Float Control Valve1 product

- Floating Ball Valve3 products

- Fluorine Lined Single Seat Control Valve1 product

- Foot Valve1 product

- Forged Cryogenic Trunnion Ball Valve1 product

- Forged Floating Ball Valve1 product

- Forged Steel Ball Valve3 products

- Forged Steel Check Valve1 product

- Forged Steel gate Valve1 product

- Forged Steel Globe Valve1 product

- Forged Trunnion Ball Valve1 product

- Fully Welded Ball Valve1 product

- Gate Valve13 products

- Globe Valve14 products

- Hastelloy C276/B3 Ball Valve2 products

- Hastelloy C276/B3 Butterfly Valve2 products

- Hastelloy C276/B3 Check Valve2 products

- Hastelloy C276/B3 Dual Plate Check Valve1 product

- Hastelloy C276/B3 Floating Ball Valve1 product

- Hastelloy C276/B3 Gate Valve1 product

- Hastelloy C276/B3 Globe Valve1 product

- Hastelloy C276/B3 Lug Butterfly Valve1 product

- Hastelloy C276/B3 Swing Check Valve1 product

- Hastelloy C276/B3 Trunnion Mounted Ball Valve1 product

- Hastelloy C276/B3 Valve8 products

- Hastelloy C276/B3 Wafer Butterfly Valve1 product

- Inverted Bucket Steam Trap1 product

- Investment Casting Ball Valve10 products

- Iron Globe Valve3 products

- Jacketed Ball Valve1 product

- Jacketed Plug Valve1 product

- Knife Gate Valve5 products

- Lift Check Valve1 product

- Lubricated Plug Valve1 product

- Lug Butterfly Valve1 product

- Lug Triple Offset Butterfly Valve1 product

- Monel Butterfly Valve2 products

- Monel Check Valve2 products

- Monel Dual Plate Check Valve1 product

- Monel Gate Valve1 product

- Monel Globe Valve1 product

- Monel Lug Butterfly Valve1 product

- Monel Swing Check Valve1 product

- Monel Valve6 products

- Monel Wafer Butterfly Valve1 product

- Mud Gate Valve1 product

- Needle Valve1 product

- Non Lubricated Plug Valve1 product

- Non Rising Stem Gate Valve4 products

- Non Slam Swing Check Valve1 product

- NRS Carbon steel Gate Valve1 product

- NRS Cast Iron Gate Valve1 product

- NRS Ductile Iron Gate Valve1 product

- Orbit Plug Valve1 product

- Pilot Operated Pressure Reducing Valve1 product

- Pilot Operated Safety Valve1 product

- Plug Valve8 products

- Plunger Valve1 product

- Pneumatic 3 Way Ball Valve2 products

- Pneumatic Actuated 2 Piece Ball Valve1 product

- Pneumatic Actuated 2 Piece Flanged Ball Valve1 product

- Pneumatic Actuated 3 Piece Ball Valve2 products

- Pneumatic Actuated Ball Valve9 products

- Pneumatic Actuated Butterfly Valve4 products

- Pneumatic Actuated Flanged Butterfly Valve1 product

- Pneumatic Actuated Gate Valve1 product

- Pneumatic Actuated Globe Type Control Valve1 product

- Pneumatic Actuated Globe Valve0 products

- Pneumatic Actuated Lug Butterfly Valve1 product

- Pneumatic Actuated Three Piece Ball Valve1 product

- Pneumatic Actuated Three Piece Flanged Ball Valve1 product

- Pneumatic Actuated Three Way Ball Valve1 product

- Pneumatic Actuated Three Way Flanged Ball Valve1 product

- Pneumatic Actuated Trunnion Ball valve2 products

- Pneumatic Actuated Two Piece Ball Valve2 products

- Pneumatic Actuated Valve17 products

- Pneumatic Actuated Wafer Butterfly Valve1 product

- Pneumatic Angle Control Valve1 product

- Pneumatic Bidirectional Knife Gate Valve1 product

- Pneumatic Cage Control Valve1 product

- Pneumatic Casting Trunnion Ball Valve1 product

- Pneumatic Control Valve9 products

- Pneumatic Double Seat Control Valve1 product

- Pneumatic Flow Control Valve1 product

- Pneumatic Knife Gate Valve3 products

- Pneumatic Single Seat Globe Control Valve1 product

- Pneumatic Sleeve Type Control Valve1 product

- Pneumatic Trunnion Ball Valve0 products

- Pneumatic Trunnion Forged Ball Valve1 product

- Pneumatic Unidirectional Knife Gate Valve1 product

- Pressure Reducing Valve6 products

- Pressure Relief and Sustaining Valve1 product

- Pressure Safety Valve1 product

- Pressure Seal Check Valve1 product

- Pressure Seal Gate Valve1 product

- Pressure Seal Globe Valve1 product

- Rising Stem Carbon Steel Gate Valve1 product

- Rising Stem Cast Iron Gate Valve1 product

- Rising Stem Ductile Iron Gate Valve1 product

- Rising Stem Gate Valve5 products

- Rising Stem Stainless Steel Gate Valve1 product

- Safety Valve6 products

- Simplex Basket Strainer1 product

- Single Orifice Air Valve1 product

- Single Plate Check Valve1 product

- Slab Gate Valve1 product

- Slurry Knife Gate Valve1 product

- Speciality Valve66 products

- SS304 Bellow Seal Globe Valve1 product

- SS316 Bellow Seal Globe Valve1 product

- Stainless Steel Globe Valve1 product

- Steam Pressure Reducing Valve1 product

- Steam Safety Valve1 product

- Steam Trap5 products

- Steel Globe Valve3 products

- Strainers3 products

- Suction Diffuser1 product

- Super Duplex Ball Valve2 products

- Super Duplex Butterfly Valve2 products

- Super Duplex Check Valve2 products

- Super Duplex Dual Plate Check Valve1 product

- Super Duplex Floating Ball Valve1 product

- Super Duplex Gate Valve1 product

- Super Duplex Globe Valve1 product

- Super Duplex knife Gate Valve1 product

- Super Duplex Lug Butterfly Valve1 product

- Super Duplex Swing Check Valve1 product

- Super Duplex Trunnion Ball Valve1 product

- Super Duplex Valve9 products

- Super Duplex Wafer Butterfly valve1 product

- Surge Anticipator Valve1 product

- Swing Check Valve1 product

- T Pattern Piston Check Valve1 product

- Thermal Safety Valve1 product

- Thermodynamic Steam trap1 product

- Thermostatic Steam trap1 product

- Through Conduit Knife Gate Valve1 product

- Titanium 3 Piece Ball Valve1 product

- Titanium Ball Valve7 products

- Titanium Butterfly Valve2 products

- Titanium Check Valve2 products

- Titanium Dual Plate Check Valve1 product

- Titanium Floating Ball Valve1 product

- Titanium Gate Valve1 product

- Titanium Globe Valve1 product

- Titanium Gr.2 2pc Flanged Ball Valve1 product

- Titanium Gr.2 3pc Ball Valve1 product

- Titanium Gr.5 2pc Flanged Ball Valve1 product

- Titanium Gr.5 3pc Ball Valve1 product

- Titanium Lug Butterfly Valve1 product

- Titanium Swing Check Valve1 product

- Titanium Trunnion Mounted Ball Valve1 product

- Titanium Valve13 products

- Titanium Wafer Butterfly Valve1 product

- Triple Duty Valve1 product

- Triple Eccentric Butterfly Valve1 product

- Triple Offset Butterfly Valve3 products

- Trunnion Ball Valve3 products

- Twin Seal Plug Valve1 product

- Unidirectional Knife Gate Valve1 product

- Wafer Butterfly Valve1 product

- Wafer Triple Offset Butterfly Valve1 product

- Water Pressure Reducing Valve1 product

- Weld Neck Flange0 products

- Y Strainer1 product

- Y Type Globe Valve1 product