- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

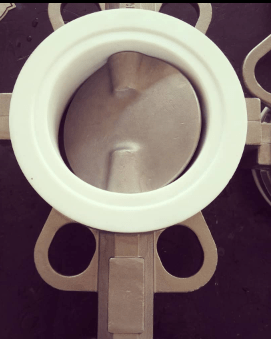

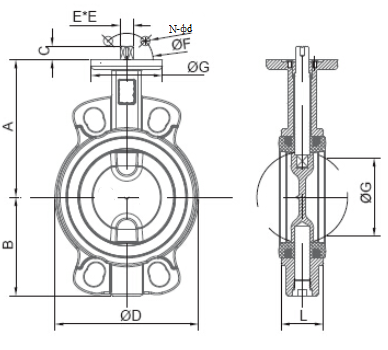

Alloy Wafer Butterfly Valve

Middleeast Valve manufactures high quality Alloy Wafer Butterfly Valve. With the capability of providing efficient and reliable flow control in a broad range of rigorous industrial applications we feature an alloy build that resists corrosion while maintaining high performance, these valves are a prerequisite for use in hostile environments where reliability is key.

Definition

An Alloy Wafer Butterfly Valve is a quarter-turn butterfly valve that contains a round disc supported by a shaft. Excellent resistance to chemical harshness, high pressure, and high temperature is given by the alloy body, thus a perfect application where harsh conditions have to be used. A wafer construction with ease of usage in flanged piping systems.

Important Components

- Valve Body: Formed by durable alloys like stainless steel, Inconel, or Monel, with extra corrosion protection.

- Disc: A circular metal disc that turns to regulate flow.

- Stem: Links the disc to the actuator and guides its motion.

- Seal/Seat: Usually constructed of elastomers such as EPDM, PTFE, or Viton, to provide close shut-off when the valve is closed.

- Actuator: May be manual, pneumatic, or electric to operate the valve.

Working Mechanism

The function of the Alloy Wafer Butterfly Valve is straightforward: when actuated, the stem will turn, turning the disc and regulating the fluid flow through the valve. When closed, the disc will prevent flow, while an open valve will have complete passage.

Benefits

- Lightweight, compact construction

- Fast operation with 90-degree rotation

- Low pressure drop and energy-saving

- Corrosion-resistant, erosion-resistant, and resistant to high temperatures

- Able to handle a range of media types, from gases to liquids to slurries

Industries Best suited for application in:

- Chemical Processing

- Water & Wastewater Treatment

- Oil & Gas

- HVAC Systems