- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

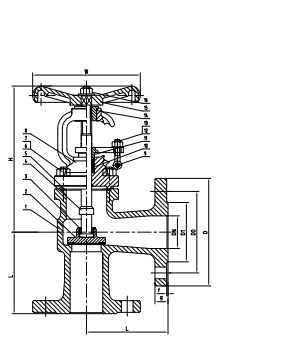

Angle Globe Valve Suppliers in Dammam: Compact Solution for Directional Flow Control

Middleeast Valve is the top Angle globe valve suppliers in Dammam. It is a variant of the regular globe valve, in which the inlet and outlet ports are positioned at 90° angles. The arrangement minimizes the requirement of an additional elbow within the piping system, rendering it space-efficient and economical for fluid systems where there is a requirement for directional changes as well as flow control or shut-off.

Working Mechanism:

The valve operates by rotating the handwheel, moving the stem and disc axially in a vertical direction. On the motion of the disc away from the seat, flow in 90-degree direction is permitted. Closed position is such that the disc closes over the seat and shuts off the flow completely. This configuration minimizes pressure loss and maximizes flow efficiency on corner installations.

Advantages:

1)Decreases need for extra piping bends

2)Very good shut-off and throttling capability

3)Compact design ideal for limited spaces

4)Reduces pressure drop and turbulence

5)Simple to maintain and long lasting

Components:

1)Valve Body: Cast in L-shape with 90° flow path

2)Disc (Plug): Gyrates vertically to regulate flow

3)Seat: Ensures tight sealing on valve closure

4)Stem: Connects the disc to the handwheel or actuator

5)Bonnet: Protects and covers the moving parts

Industries:

1)Oil and gas

2)Chemical processing

3)Power generation

4)Water treatment

Description

Body Material: Cast Iron , Cast steel , Ductile Iron, AISI SS 304,316,316L,317,317L

Size Range: 2 inches to 18 inches

Pressure :Class150 to Class1500

Class Range: CLASS 150~ 2500

Ends: Flanged, Buttweld, Socket weld, Threaded

Operations: Handwheel operated, Gear Operated , Electric Actuated and Pneumatic Actuated.