- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

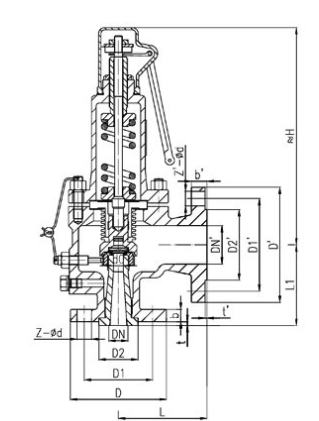

Bellow Safety Valve Suppliers in Oman: Enhancing System Protection with Precision

Middleeast is the top Bellow safety valve suppliers in Oman. It provides high-quality and dependable bellow safety valves for diverse industrial uses.

Working Mechanism:

It works on the principle of measuring the pressure inside a system. As pressure increase to set point, spring is pushed, and valve is opened, letting out excess pressure. When pressure fall to safe point, the spring close valve. The bellows ensure the valve is closed and prevent leakage, even under high pressure.

Components of Bellow Safety Valve:

1)Bellows: The flexible sealing part which ensures pressure integrity.

2)Spring: Used to maintain enough force to shut the valve until the pressure overcomes the threshold limit.

3)Valve Seat: The region that the valve seats tightly to block leaks.

4)Actuator: Switches the position of the valve based on a change in pressure.

Advantages:

1)Prevents Overpressure: Saves equipment and people from overpressure by releasing excess pressure.

2)Leakage Free Operation: The bellow provide tight seal, avoiding leak.

3)Durable Design: Made to endure harsh condition for long term performance.

4)Cost-Effective: Saves on repairs and replacements by reducing damage to systems.

Industries:

1)Oil & Gas

2)Petrochemical

3)Power Generation

4)Chemical Processing

5)Water Treatment

6)Pulp and Paper

7)Marine industry

Description:

Body material: Cast Iron, WCB, SS304, SS316, Ductile Iron.

Class: PN10 – PN450, 150 – 2500.

Size: 1/2”- 40”.

Ends: Socket weld butt weld, flanged, threaded.