- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

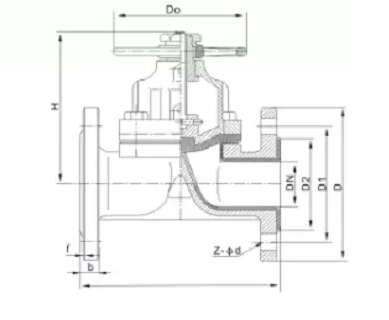

Cast Iron Diaphragm Valve Supplier in Qatar: Cost-Effective Flow Control Solution

Middleeast valve is the largest Cast Iron Diaphragm Valve Manufacturer in UAE. It is is a type of valve used to control the flow of fluids in a pipeline.

A cast iron diaphragm valve is linear motion valve utilizing a deformable diaphragm to control fluid flow. The valve body is made of cast iron, which is extremely strong, long-lasting, and cost-effective. It is typically used for pipeline shut-off and throttling duties.

Key Elements of a Cast Iron Diaphragm Valve:

1)Body: Made from cast iron for mechanical strength and long life

2)Diaphragm: Rubber or elastomer flexible component that opens and closes the valve

3)Bonnet: Encloses the top of the valve and houses the diaphragm actuator

4)Compressor: Squeezes the diaphragm downwards to close the valve

5)Actuator or Handwheel: Offers manual or automatic operation

Working Mechanism:

The valve operate by moving diaphragm up and down by a compressor mounted on handwheel or actuator. When diaphragm is forced against valve seat, it closes the flow- when it is removed, fluid can pass. This efficient but simple mechanism offers little leakage and contamination.

Advantages of Cast Iron Diaphragm Valve:

1)Corrosion and abrasion resistance

2)Easy maintenance and operation

3)Leak-proof sealing

4)Suitable for both on/off and throttling service

5)Economical solution to the requirements of most industries

Industries:

1)Water Treatment

2)Chemical Processing

3)Mining

4)Power Plants