- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Cryogenic Pneumatic Globe Valve Supplier in Doha – Automated Flow Control

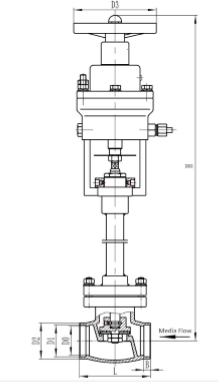

Middleeast valve is the leading Cryogenic Pneumatic Actuated Globe Valve Supplier in Doha. It is designed to provide precise flow control and outstanding reliability in mission-critical cryogenic service, providing maximum performance and safety in low-temperature systems.

Working Mechanism:

It works by using pneumatic pressure to move the actuator, which moves the stem and the disc. Through the moving of the disc, it opens or closes the valve controlling the cryogenic fluid. The globe type of valve facilitates precise fluid control, and pneumatic actuation enables the valve to perform the flow in a smooth and reliable manner even when operating under extreme conditions.

Key Parts:

1)Valve Body: The strong body made of material that can tolerate very low cryogenic temperatures and yet retain its structural strength.

2)Globe Valve Seat: One of the main parts that aid in forming a good seal while closing the valve to avoid any leakage and enable effective flow regulation.

3)Pneumatic Actuator: The device responsible for regulating the opening and closing of the valve through compressed air used to actuate the internal parts of the valve.

4)Stem and Disc: It connects the actuator to the disc’s movement and regulates its flow of fluid.

5)Bonnet and Packing: Shields the stem and other components internally, providing good insulation and leakage prevention in cryogenic conditions.

Advantages:

1)Precise Valving of Fluid

2)It can withstand extremely low temperatures.

3)Minimal maintenance

4)Risk of system failure

5)Efficient Operation

Industries:

1)LNG

2)Oil and gas

3)Chemical processing

4)Aerospace

Description:

Body Material: Cast Iron, Cast Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9) , Ductile Iron, Stainless Steel [ SS316 , SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3,F55, F91 ]

Class: 150 – 800, PN10 TO PN100

Size: 1/2” – 24”

Ends: Butt welded, Socket welded, Threaded, Flanged.