- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

Duplex Ball Valve

Middleeast valve is the foremost Duplex Ball Valve suppliers in Bahrain. A duplex ball valve is a type of valve that utilizes a ball with a hole through its center to control the flow of fluids. The term “duplex” refers to the valve’s construction, typically made from duplex stainless steel.

Duplex stainless steel is known for its superior strength and corrosion resistance, making it ideal for demanding environments. These valves are widely used in industries such as oil and gas, petrochemical, and marine, where durability and reliability are paramount.

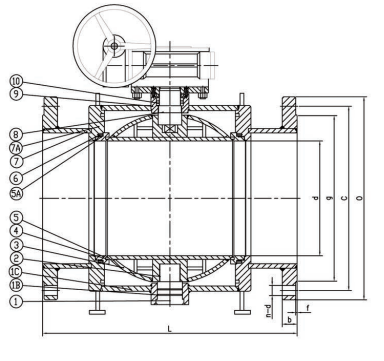

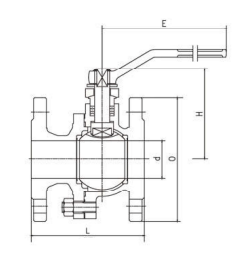

The working principle of a duplex ball valve is relatively straightforward yet highly effective. The valve consists of several key components:

- Body: The main structure housing the internal components.

- Ball: A spherical element with a hole (bore) through the center.

- Stem: A shaft connected to the ball, used to rotate it.

- Seats: Ring-shaped components that provide a seal between the ball and the valve body.

- Actuator: A mechanism used to rotate the stem and ball, which can be manual or automated.

When the valve is in the open position, the bore of the ball aligns with the pipeline, allowing fluid to flow through. Rotating the ball 90 degrees using the stem and actuator moves the bore perpendicular to the pipeline, effectively stopping the flow. The seats ensure a tight seal, preventing leaks when the valve is closed.

Duplex ball valves serve several crucial functions in industrial applications:

- Flow Control: They regulate the flow of fluids, allowing for precise control over the process.

- Isolation: These valves can completely shut off fluid flow, providing a reliable method for isolating sections of a pipeline for maintenance or emergency situations.

- Pressure Management: By controlling the flow rate, duplex ball valves help manage pressure within the system, ensuring safe and efficient operation.

- Directional Control: In multi-port configurations, duplex ball valves can direct the flow of fluids in different directions, facilitating complex piping arrangements.

Duplex ball valves offer a range of features that make them suitable for demanding industrial environments:

- High Strength and Durability: Made from duplex stainless steel, these valves can withstand high pressures and extreme temperatures, ensuring long service life.

- Corrosion Resistance: The material’s excellent resistance to corrosion makes duplex ball valves ideal for harsh environments, including those with exposure to seawater and aggressive chemicals.

- Tight Sealing: Advanced seat designs ensure a tight seal, minimizing the risk of leaks and enhancing safety.

Duplex Ball Valve suppliers in Bahrain offering exceptional strength, durability, and reliability. Their ability to control, isolate, and manage fluid flow makes them indispensable in industries where performance and safety are critical.

Description:

Body: Duplex Stainless Steel ( A890/A995 1B CD4MCuN, A890/A995 2A CE8MN, A890 1A/A995 3A CD6MN, A890/A995 4A CD3MN, A890 1C CD3MCuN, A890/A995 5A CE3MN). Nominal Size: DN50 to DN400.

Nominal Pressure: Class150 to Class900, PN10 to PN64.

Operations: Lever operated ball valve, electric actuated ball valve, pneumatic actuated ball valve, gear operated ball valve

Ends: Flanged, Butt weld, Socket weld, Threaded