- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

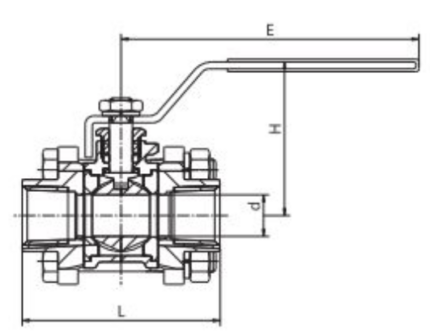

Forged Steel Ball Valve Suppliers in UAE: Durable Solution for High-Pressure Flow Control

Middleeast Valve is a top Forged Steel ball valve suppliers in UAE. These valves are often made using a forging technique, which entails shaping and compressing hot metal into the required shape, it is known as a “forged” product. The valve’s strength and durability are improved throughout the forging process, making it appropriate for use in high-pressure and high-temperature applications.

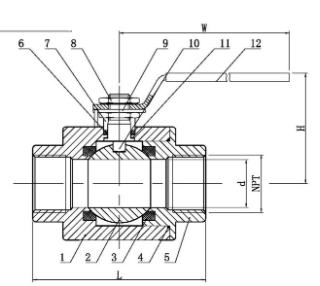

Key Components of Forged Steel Ball Valve:

- Forged Steel Body: It delivers high tensile strength and pressure resistance.

- Ball: Employ spin to control fluid flow.

- Seats and Seals: Ensure they close firmly and prevent leaks.

- Stem/ Packing: The ball is linked to the handle or actuator through the stem and packing.

- Actuator: Manual or automatic operation is facilitated through an actuator or handle.

Working Mechanism:

There is a central bore within the valve body of a spherical ball that rotates to control forged steel ball valves. The bore allows the flow of fluid when it is aligned with the flow. The flow is halted when the ball is rotated 90 degrees. Enhanced resistance to thermal expansion and pressure is offered by the forged body.

Description:

Material: A105, F11, F22, F51, LF2, F304, F304L, F316, F316L

Class: 150-2500; PN25-PN450

Ends: Flanged, Socket weld, Buttweld, Threaded

Size: ½’’ to 48’’

Operation: Electric actuated, Pneumatic actuated, Gear operated, Lever operated